Air compressor unloader valve

A reciprocating air compressor is a positive displacement mechanical device that uses a cylinder and crankshaft-driven piston to air compressor unloader valve compressed air. An unloader valve is a small and essential part that ensures the effective, efficient operation of a reciprocating compressor. A compressor unloader valve is a small part, usually sized between 4 and 5 inches.

Air is used in rotary screw compressors to keep the rotors turning, and when air is compressed, it gets hot. The unloader valve releases this excess pressure so that the rotors do not overheat and so that they can continue compressing incoming air. This minimizes friction loss within the rotary screw compressor and leads to more productivity. This article will discuss the purpose of the unloader valve and how it can help improve compressor performance. An unloader valve is a device used in rotary screw compressors to release excess pressure. When the compressor is running, this valve opens and allows compressed air to escape so that the rotors do not overheat. It also minimizes friction loss within the compressor, leading to increased productivity.

Air compressor unloader valve

Follow along with the video below to see how to install our site as a web app on your home screen. Note: This feature may not be available in some browsers. This website or its third-party tools process personal data e. To learn more, please refer to the cookie policy. In case of sale of your personal information, you may opt out by sending us an email via our Contact Us page. To find out more about the categories of personal information collected and the purposes for which such information will be used, please refer to our privacy policy. You accept the use of cookies or other identifiers by closing or dismissing this notice, by scrolling this page, by clicking a link or button or by continuing to browse otherwise. How to install the app on iOS. Log in Register. Search titles only. Search Advanced search…. Forums New posts Search forums. Media New media New comments Search media. Everywhere Threads This forum This thread. New posts.

When that happens, the pilot opens and pressurizes the unloader valve, causing the unloader valve to open and excess air from the compressor to vent to atmosphere.

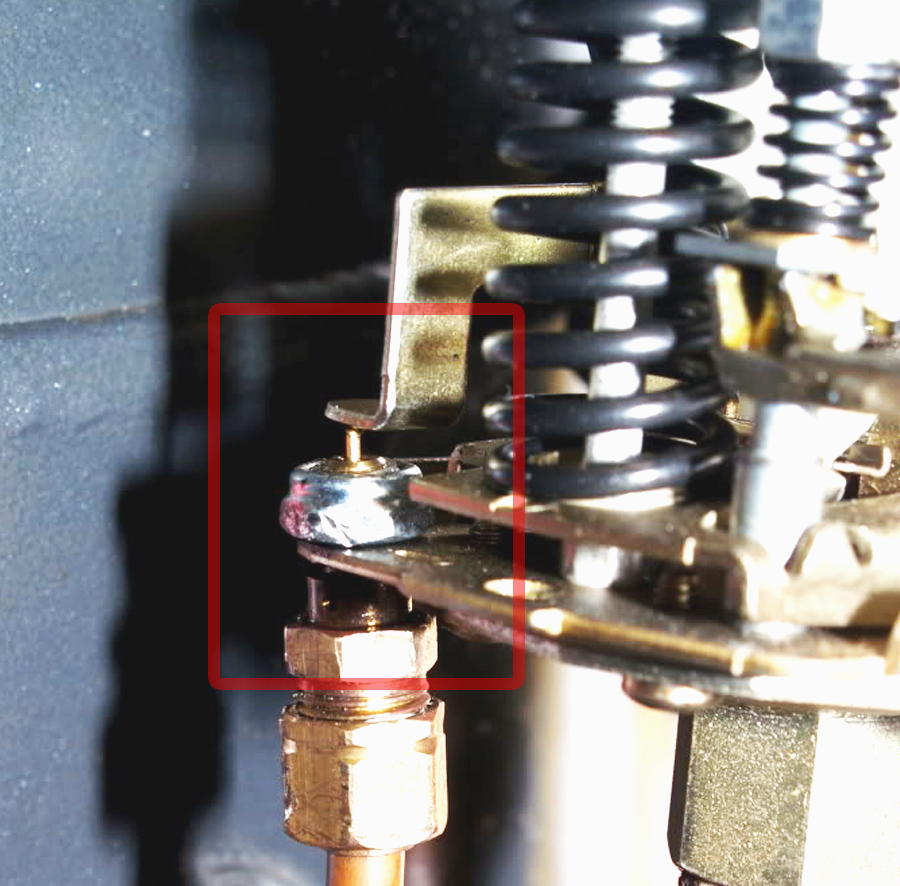

The air compressor unloader is valve is a small, but important, part of the reciprocating piston compressor. It blows off the pressure inside the discharge pipe when the compressor stops. There is another type of unloader valve , which can be found at the inlet of rotary screw compressors , also called inlet valve or loading valve. Air compressor unloader valve. The output of the piston compressor is connected through a pipe to the air receiver. When the compressor stops, the pressure in this pipe is blown off to 0 bar atmosphere. This is the ssssssshhh sound you will here when the compressor stops.

The air compressor unloader valve provides a critical function in preparing your air compressor to restart. A failed air compressor unloader valve is one of the most common reasons why your air compressor cannot restart after you have used air from the compressor tank. When the the air compressor unloader valve is working correctly, the pressure in the tank has dropped to below the normal cut in pressure level of the pressure switch, the pressure switch trips to allow power to flow through it, and the motor starts. If the unloader valve has failed when the motor tries to start quite often the motor will lug struggle to start and typically a breaker will trip or a fuse will blow. Compressor unloader valves are common pieces of equipment on many types of air compressors including reciprocating, rotary screw and even gasoline or other fossil fueled air compressors. This Fix My Compressor website is focused on the do it yourself and small workshop air compressor and most of these are reciprocating type air compressors.

Air compressor unloader valve

There are few components on an air compressor that can multi-task quite like the piloted unloader valve. This single component can activate an engine idle control, divert air from the tank when it reaches the top pressure setting and can reduce oil consumption by equalizing pressure between the pump and check valve. The following blog post will help you understand the piloted unloader valve by pointing out its components, explaining how it works and describing the adjustment process. The diagram below shows the components of our most common piloted unloader valve, part number B. Piloted unloader valves combine a pilot valve and an unloader valve to run an air compressor continuously. While this type of valve is most commonly used on gas-powered air compressors, it can also be used on electric models. While the air compressor is running, the pilot remains closed until the pressure reaches the unload setting. When that happens, the pilot opens and pressurizes the unloader valve, causing the unloader valve to open and excess air from the compressor to vent to atmosphere. As the compressed air is used and the pressure drops to the load setting, the pilot closes and depressurizes the unloader valve.

Franchi momentum 350 legend magazine

Plastic line is an oil pressure gauge. The air compressor unloader is valve is a small, but important, part of the reciprocating piston compressor. Unloader valves are located on top of or inside the pressure switch in smaller reciprocating air compressors. It causes the air trapped on the main piston to be released through the governor exhaust 11 at the top of the air compressor unloader valve A new unloader valve can save you significant time and expenses. Unloader Valve: Its Purpose. Unloader circuit runs into this unit in front of the oil pump circuit. I have no reference for how this is supposed to work. Several years ago, I purchased a used Kellogg American two stage compressor sold under the name Henke Pacemaker. An electrical unloader valve is controlled by an outside source. On the left side of the big valve we see the compressor output top and the connection to the air tank bottom.

You are here Home » Automotive Tools » Air compressor.

Several years ago, I purchased a used Kellogg American two stage compressor sold under the name Henke Pacemaker. Incorrect air pressure When setting up the unloader valve, be sure to set it at the correct pressure. Bypassing: A bypassing type of unloader valve allows the excess compressed air to escape, thus keeping it from building up within the compressor. Some common problems with unloader valves and their solutions: Recommend Products. After the pressure releases, identify the unloader valve. The unloader valve then closes and the pressure begins to build again and repeats the cycle. The compressor pump, which is attached to the motor shaft, also stops. I'm slightly confused by a lot of the above Loosen locknut 1 by turning counterclockwise several full turns. June 4th, 3 Comments. Posted on: June 28, A reciprocating air compressor is a positive displacement mechanical device that uses a cylinder and crankshaft-driven piston to produce compressed air.

Excuse, that I interrupt you, but I suggest to go another by.