Casing capping wiring

Join TheConstructor to ask questions, answer questions, write articles, and connect with other people.

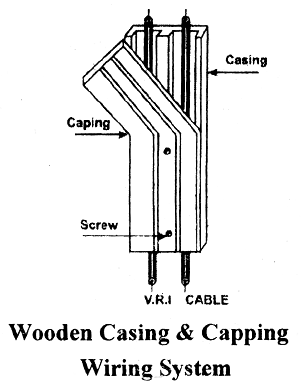

Despite being one of the oldest methods of wiring, casing capping is still used extensively today. This form of wiring is one of the most fundamental. Putting PVC-insulated wire in a plastic container and then capping the whole thing is what is meant by the term "casing capping. Wires are routed via grooves in a rectangular strip that serves as the casing. Casing capping is a fundamental sort of electric wire arrangement. Various shapes and sizes of moulded domes are utilised to cover the wires.

Casing capping wiring

Casing Capping is one of the oldest wiring systems and has been very popular and frequently used. This post will discuss what is Casing Capping Wiring, its installation procedure, types of joints, 2 way and 3 way design, advantages and disadvantages. The process of connecting different accessories for distributing electrical energy from supplier to home appliances such as lamps, fans and other domestic appliances is known as Electrical Wiring. It is one of the simplest forms of electric wiring systems. Casing is a rectangular strip where the cables run through it having grooves. The durability of this wiring system is 20 years approximately. It is mostly used in Home and Office spaces. Sheathed wiring systems are used for industrial purpose as it provides double insulation. Before installing, a 3mm round insulator is used between casing and the wall to prevent the humidity of the wall affecting the casing. This wiring can be installed in both vertical and horizontal positions. Different types of joints are used in this type of wiring system such as T joint, L-joint and Bridge joint etc. What is Casing Capping Wiring — Installation, Advantages, Disadvantages Casing Capping is one of the oldest wiring systems and has been very popular and frequently used. Madhuri Madhuri is a B.

Among the joints are T-joints, L-joints, and a bridge joint. You will receive a link and will create a new password via email. She is an Author, Editor and Partner at Electricalfundablog, casing capping wiring.

Casing and caping is one of the oldest and most popular wiring systems still in use today. The casing and capping system is often used for household wiring, wire distribution, protection to other wiring systems, offices, and devices with low voltage use. The casing is commonly a rectangular strip, and its channel and cap are usually grey or white. Press and fit is the most prevalent wiring type, with one part on the bottom surface and another on top. The installation process is pretty straightforward. First, the bottom part is attached to the walls.

Casing wiring is generally adopted for low pressure installations. Here V. Casing generally used for installation is about 44 mm wide and 16 mm in thickness height. However, for cables of higher sizes, mm wide and proportionally higher in thickness casings are also in use. Casings may be 5. Lengths of about 2. There are two grooves in each casing.

Casing capping wiring

Agra, Uttar Pradesh. Troop Bazar, Hyderabad Shop No. Hyderabad, Telangana. Dhuri, Dist. Sangrur, Punjab. Ahmedabad, Gujarat. Near Bhiwadi, Tijara, Dist. Alwar, Rajasthan. Company Video. Pune, Maharashtra.

Itscarlyjane onlyfans leak

Next article. It can also be installed in places having acids and alkalize. The system has a year lifespan and performs admirably in homes and offices. PVC has the highest level of chemical resistance available, making it the most durable material on the market. They offer insulation and electrical safety and support the distribution load of the wires in accordance with their capacity. This type of wiring system is also known as wireways. Go to mobile version. The electrical installation provides a safe source for connecting electrical appliances of a consumer with electrical supply through over current and earth leakage protection. Green Thumb Local. In order to cover and control these wires inserted into the grooves, another thin rectangular type strip is fixed above the casing through screws, which is called capping. Where the casing wiring system has to be necessarily adopted in situations under 1 and 2 above, only metallic wireways shall be used. Casing Capping Wiring- Installation means the act of installing something. Materials such as PVC are pretty hard to press, and their application is much easier with sliding. When you join you get additional benefits. Leave a Reply Cancel reply Your email address will not be published.

Search This Blog. Casing capping wiring Definition instantiation Advantages Applications. This is one of the simple forms of electrical wiring systems.

It is also difficult to re-apply accessories that have already been used in the casing-capping wiring. The system using PVC wireways shall not be adopted in residential buildings or other locations where there is a risk of tampering. Electric wire systems typically have a case and cap diameter of 1. Installing phase and neutral wires in separate slots make repairing straightforward and cost-effective. Moreover, it also has no danger of worm-eating by white ants. All surfaces shall have a smooth finish inside and outside. When compared to a steel conduit and sheeted wire system, it is less expensive. This post will discuss what is Casing Capping Wiring, its installation procedure, types of joints, 2 way and 3 way design, advantages and disadvantages. Grilling: One of the most common and versatile ways to handle telephone cabling is using a grilled-fit casing and cap. What makes TMT plus casing and capping a high quality casing and capping wire for electrical: It has two locking mechanisms. Casing Capping Wiring- Installation means the act of installing something. Mention the application of the casing wiring system? Go to mobile version. Case and Cap of Casing Wiring System. Casing and Capping.

I congratulate, it is simply excellent idea

I consider, that you commit an error. Write to me in PM, we will discuss.

I like it topic