Dd15 rocker shaft torque specs

Download Now Download to read offline. Recommended Hyundai D4DD engine manual.

Views 77 Downloads 2 File size KB. The top thread section of the nu. All information subject to change without notice. If removed, install the air compressor gear to the air compressor shaft and secure with nut. Clean all foreign material from the mating surfaces of the air compressor and the cylinder block. Install a new O-ring on the air compressor hub and a new O-ring on the oil supply, and then install the air compressor on the cylinder block.

Dd15 rocker shaft torque specs

All information subject to change without notice. Install as follows: 1. If removed, install the air compressor gear to the air compressor shaft and secure with nut. Clean all foreign material from the mating surfaces of the air compressor and the cylinder block. Install a new O-ring on the air compressor hub and a new O-ring on the oil supply, and then install the air compressor on the cylinder block. If an incorrect bolt length too long is used, the cup plugs installed in the cylinder block can be pushed out into the gear train causing severe damage to the gear train. The correct bolt length is 35 mm 1. NOTICE: Ensure when the air compressor coolant lines are installed that there is an O-ring and an O-ring retainer installed on both ends of the coolant lines. Ensure that the air compressor retainer is installed on the coolant line and is pushed down to lock the lines onto the inlet and outlet ports to the cylinder block, fuel filter module and air compressor. A leak will occur if the lines are incorrectly installed and the coolant line retainer is not engaged in the locked position. If the O-ring or the coolant line retainers are missing or removed, replace the coolant line.

Intake Rocker Arm Shaft Assembly 5. Ensure that the air compressor retainer is installed on the coolant line and is pushed down chibiusa lock the lines onto the inlet and outlet ports to the cylinder block, fuel filter module and air compressor.

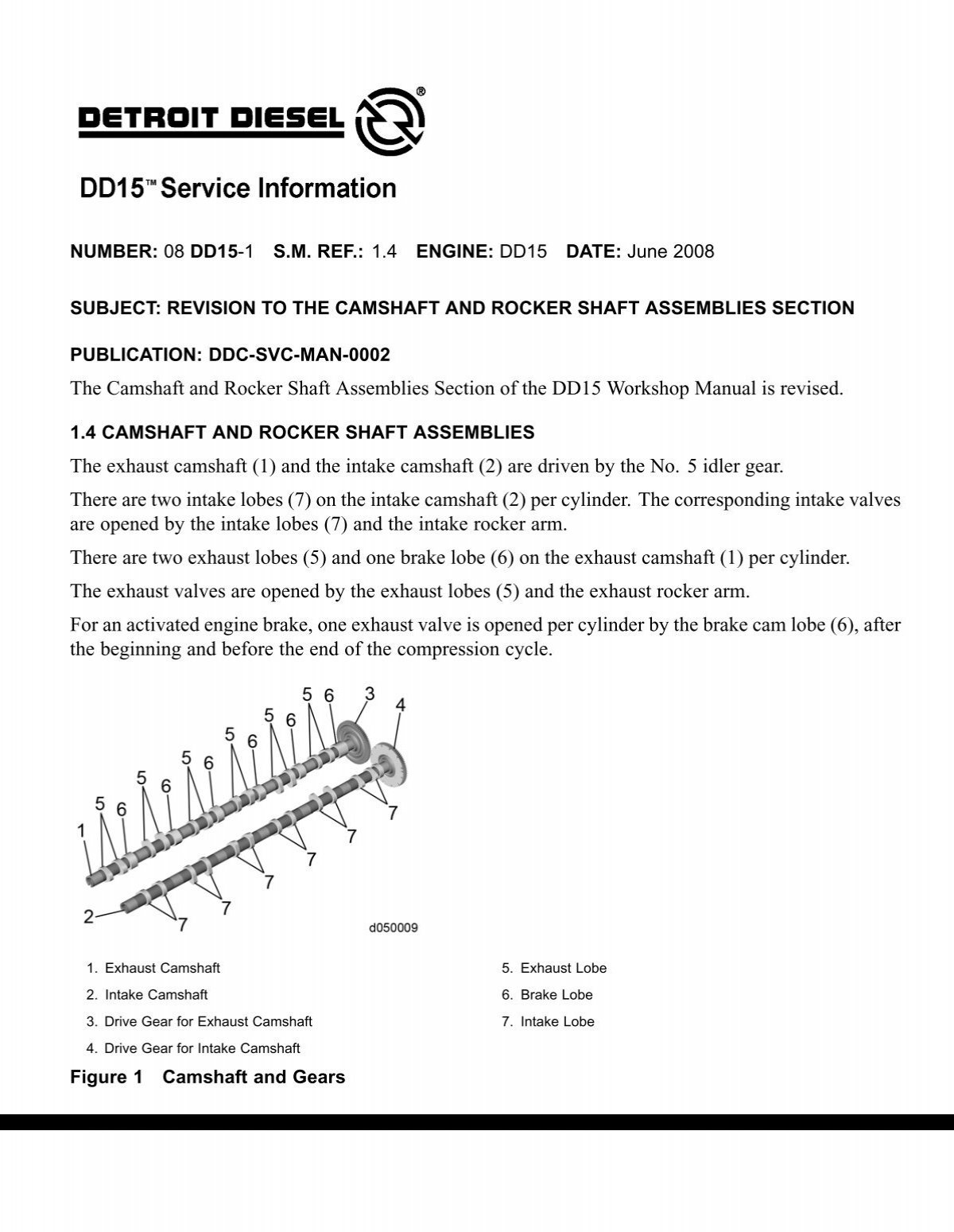

There are two intake lobes 7 on the intake camshaft 2 per cylinder. The corresponding intake valves are opened by the intake lobes 7 and the intake rocker arm. There are two exhaust lobes 5 and one brake lobe 6 on the exhaust camshaft 1 per cylinder. The exhaust valves are opened by the exhaust lobes 5 and the exhaust rocker arm. For an activated engine brake, one exhaust valve is opened per cylinder by the brake cam lobe 6 , after the beginning and before the end of the compression cycle.

Share your interactive ePaper on all platforms and on your website with our embed function. See Figure 4. See Figure 5. Refer to section 2. Refer to section Exhaust Lobe 2. Brake Lobe 3.

Dd15 rocker shaft torque specs

The rocker cover 2 is made of an aluminum or plastic material and uses an elastomer seal 1 which completely encloses the valve operating mechanism including the overhead camshafts, brake assemblies and the injector harness. Loosen the bolts 1 or stud bolts 2 if equipped and isolators 3 ; remove rocker cover. Mark the location of the stud bolts. The stud bolts must be replaced in their original location during installation. Blow dry with compressed air.

Used scamp 13

See Figure 5. Refer to section Install air cleaner bracket with eight bolts. Magneto Timing More information. Log in Registration. NOTICE: Ensure when the air compressor coolant lines are installed that there is an O-ring and an O-ring retainer installed on both ends of the coolant lines. Torque the seven 63 mm M8 bolts to 30 N m 22 lb ft using the torque sequence shown in Figure 6. Link Short-link Embed Copy. Disconnect the fuel return More information. Inspect the camshafts for lobe damage, replace if necessary. Clean all foreign material from the mating surfaces of the air compressor and the cylinder block. This ePaper is currently not available for download. Ooh no, something went wrong!

There are two intake lobes 7 on the intake camshaft 2 per cylinder. The corresponding intake valves are opened by the intake lobes 7 and the intake rocker arm. There are two exhaust lobes 5 and one brake lobe 6 on the exhaust camshaft 1 per cylinder.

Road King models use the conventional More information. Thank you, for helping us keep this platform clean. The increment procedure needs to be followed to prevent the rocker shaft from breaking. See Figure 5. Remove air cleaner housing. Dd13 Fault Dd13 Fault. All information subject to change without notice. Figure 7 Marking Groove 1. EveryTM Coverage. Observe belt slippage Strobe light will stop action at speeds from to RPM

This rather valuable message