Forklift parts diagram

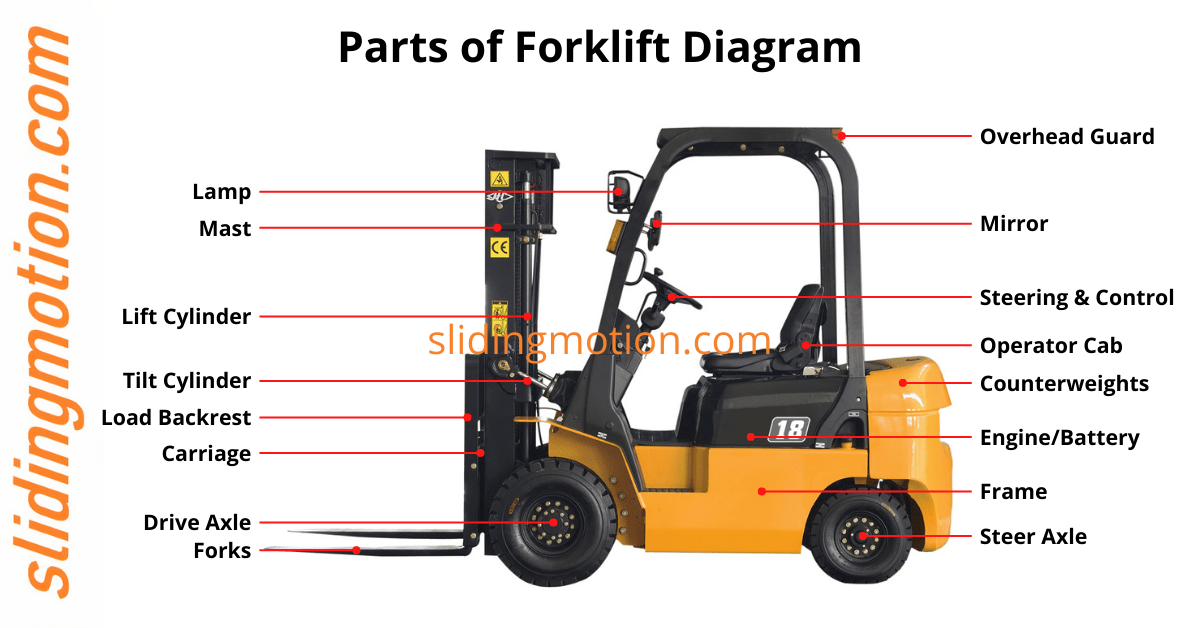

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to forklift parts diagram properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job.

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point. And this would cause the lift truck to tip forward — rendering it useless and potentially causing injury. There are two main types of forklift counterweights:. They can also consist of a single metal casting or a hollow metal container with a mix of concrete and metal.

Forklift parts diagram

For this guide we are focusing on counterbalance forklift parts. In many operations, a counterbalance forklift is usually the most common piece of support equipment in use. They are the workhorses of many operations and are called upon to work in a variety of environments including temperature extremes, harsh weather, difficult terrain and an extraordinary amount of weight and pressure due to the loads they carry. Such a wide range in cost is due to factors such as size, lift capacity, indoor vs outdoor application, accessories, and other considerations. With so much operational success riding on forklifts, keeping them serviced and in proper running condition is paramount for any company. And due to the type of work they do and the environments in which they operate, owners and maintenance staff must understand the construction and parts on a forklift to keep them in service. Forklifts come with one of two power sources, either electric or internal combustion IC :. Electric : Battery operated forklifts utilize one large battery to power the truck. This battery is located under the driver seat or in the rear of the lift, depending on the type and size lift purchased. Batteries can range from 12V to 96V and may be available in custom voltages as well. Depending on the battery size, the number of cells within the battery may vary. Battery operated lifts must be regularly charged and maintained and water levels in the battery must be kept at the correct level and topped off with distilled water when necessary. When replacing a battery, it is important to buy the right size for the capacity and type of lift used. Electric forklifts are often used in enclosed spaces, such as warehouses or manufacturing plants.

Electric forklifts are often used in enclosed spaces, such as warehouses or manufacturing plants.

The forklift is an industrial truck for lifting and transporting a load over a short distance. It serves the needs of the various warehouses and large facilities. In the 20th century, most companies started manufacturing. Nowadays, most warehouses use them. Due to that, extra time for loading and lifting material reduces and increases the work speed.

Learn about the different terminology and the various parts of a forklift truck. Use our forklift diagram for reference. Forklifts have many moving parts and pieces that allow the forklift to operate properly. Understanding the terminology of the parts and anatomy of a forklift is important for effective communication with others while on the job. Here are some of the fundamental features and parts that make up the anatomy of a forklift truck. The forklift mast is the raised vertical support that allows loads to be raised and lowered. Forklift masts come with various sections that elevate or lower the forklift carriage along with the forks. These include:. This will allow you to select a forklift that is designed to fulfill the specific needs of your applications. For more information on forklift masts, read our article Forklift Mast Types.

Forklift parts diagram

Additionally, forklifts have numerous safety devices distributed throughout the truck. Answer: It counteracts the weight on the forks and provides for the proper weight distribution of the truck. The front wheels act as the fulcrum — or balancing point.

William morris deer wallpaper

It operates by the engine or battery and uses the counterweight to balance the lifting load. This battery is located under the driver seat or in the rear of the lift, depending on the type and size lift purchased. The operator steering wheel controls movement of the rear wheels or steering wheels of the forklift. Performance cookies are used to understand and analyze the key performance indexes of the website which helps in delivering a better user experience for the visitors. Forklift Forks. Lever Controls — The lever controls allow the operator to engage the lifting mechanisms to manipulate the load. However, a strong maintenance program and diligent service in conjunction with a good working knowledge of the parts of the lift purchased will provide a long-term return on investment and one that is safe for all involved. Forklift Lever Controls. But opting out of some of these cookies may affect your browsing experience. It is similar to the automobile steering wheel. Find Your Dealer. The design of the fork is important, as it directly comes in contact with loads. For more information on forklift masts, read our article Forklift Mast Types. Lift Cylinder. The lift cylinder powers the vertical movement of the load on the mast.

Forklifts are complicated. If you don't know the difference between a load backrest and a forklift carriage, the relative benefits of simplex vs duplex masts, or the OSHA regulations regarding overhead guards, you can easily end up buying inappropriate equipment. Use my simple guide to familiarize yourself with all the most important components of a forklift truck, from wheels and tires to the range of accessories used to increase the versatility of these amazing machines.

The cookies is used to store the user consent for the cookies in the category "Necessary". In doing so, the operator can make minor adjustments to the load alignment without maneuvering the entire forklift. It prevents the slipping of the load backward or operator while working. FORKS Perhaps the most obvious of reach truck parts are the forks themselves, also known as the tynes. Find Your Region. Its design changes as per the manufacturer and type of application. Check the rating plate on the forklift for this information. They are attached to the forklift carriage and are designed to carry a load from the bottom. It is also key in releasing pressure on a pallet to allow the fork to reverse without moving the pallet with it. The operator cab serves as the control center for operating forklifts. Common fork types include. These are commonly used in sensitive industries like food and pharmaceuticals where using wood pallets could contaminate the products. It generates the power to run the forklift in different locations.

0 thoughts on “Forklift parts diagram”