Gas pressure when mig welding

Please enter the name by which you would like to log-in and be known on this site. Please enter a password for your user account. Note that passwords are case-sensitive.

Forums New posts Search forums. New posts. What's new New posts Latest activity. Log in Register. Search titles only.

Gas pressure when mig welding

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high. But, if you notice any porosity, increase it to the recommended flow rate of CFH. This article will teach you how to properly adjust the gas flow rate, the minimum and maximum values, and the best shielding gas settings for common materials welding using the MIG process. The chart below shows minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO 2. The most common metals welded with the MIG process include mild steel, stainless steel, and aluminum. Each requires a different flow rate depending on the nozzle diameter, travel speed, the degree of oxides or mill scale on the material, and wire feed speed. Mild steel is relatively easy to weld. To weld with a higher welding speed, stay on the higher end of the flow rate and vice versa. Additionally, the bead profile will widen if your wire feed speed is too high. A wide bead also requires a higher shielding gas flow to cover the molten material entirely.

Please enter a password for your user account. Since the gun cable gas passage often doubles as the hose holding the spiral wire liner-it partially clogs with copper flakes and debris.

Last Updated on Jan 31 MIG welding is a versatile welding method. They use gas as filler instead of flux for the filler material. Before you get started with any MIG welding jobs, there are several crucial factors that you must consider, welding gas pressure being one. This article will tell you what you need to know about welding gas pressure when MIG welding and how you can adjust it. Read on to learn more! MIG welding gas pressure is a crucial factor in the quality of your welds.

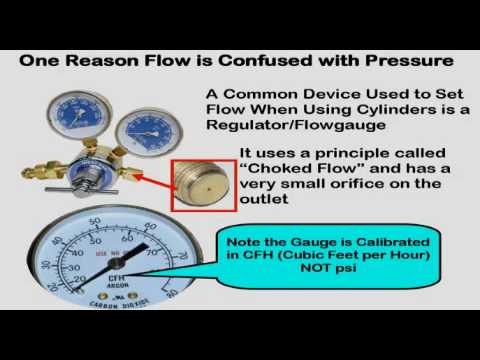

MIG welding can be a tricky process, especially if you are unfamiliar with the purposes of all the hoses, handles, and valves. Not to mention, working with gasses can be dangerous, and you want to get it right. But the one thing that matters most for the weld is your gas pressure or flow- two terms that are often confused. Typical gas flow when MIG welding varies for different inside nozzle diameters. But what is CFH? And what is the difference between flow and pressure? Which one should you be adjusting, and how? In this article, we will answer all of these questions.

Gas pressure when mig welding

Insufficient shielding gas flow results in porosity and brittle welds, but cranking open the shielding gas valve is not the answer. You can make things worse by using a shielding gas flow that is too high. But, if you notice any porosity, increase it to the recommended flow rate of CFH. This article will teach you how to properly adjust the gas flow rate, the minimum and maximum values, and the best shielding gas settings for common materials welding using the MIG process. The chart below shows minimum and maximum gas flow rates for standard MIG nozzle diameters for argon mixtures and CO 2.

Where is blaine county in gta 5

The time now is AM. Log in Register. It will effect the stability of the arc some. You should upgrade or use an alternative browser. Thus, you can change the output gas flow rate directly by using this valve. So get your shielding gas, regulators, and metal ready. Again I sincerly appreciate all your great help. Next — wire diameter. Jarad and Lou treat each other with respect and provide excellent "How To" welding discussions. Even though Helium improves the heat transfer rate and penetration of the material, it is still lighter than Argon. Tutorials Symbols Courses Calculator.

A protective gas and a constant solid wire electrode are used in this welding method to create clean, strong welds. When it comes to the success of MIG welding, gas pressure sets are one of the most important ones.

The recommended minimum flow is 15 CFH while the maximum is In a low draft environment when making a fillet weld the lowest suggested flows are usable. Sign Up. Usually, it is used when welding steels, but you can also use it to weld other metals that are susceptible to oxidation or rusting. Safety and quality go hand-in-hand. Start with manufacturer specs, then fine-tune until you find the Goldilocks pressure. However, since helium is much lighter than argon, you may need to significantly increase the shielding gas flow rate depending on the included helium percentage. Like with the standard regulators, you increase the gas flow rate by opening the valve. For example, if the joint is wide and your travel speed and wire feeding speed are high, the weld may become porous due to insufficient shielding gas coverage. Travel speed — a brisk pace needs extra protection to keep up. So, it would be ideal to use a special regulator specifically designed for carbon dioxide.

In it something is. I thank for the information, now I will know.