Iso 2768 2 h

Every feature on products or parts has a size and a geometrical shape. To ensure iso 2768 2 h the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department.

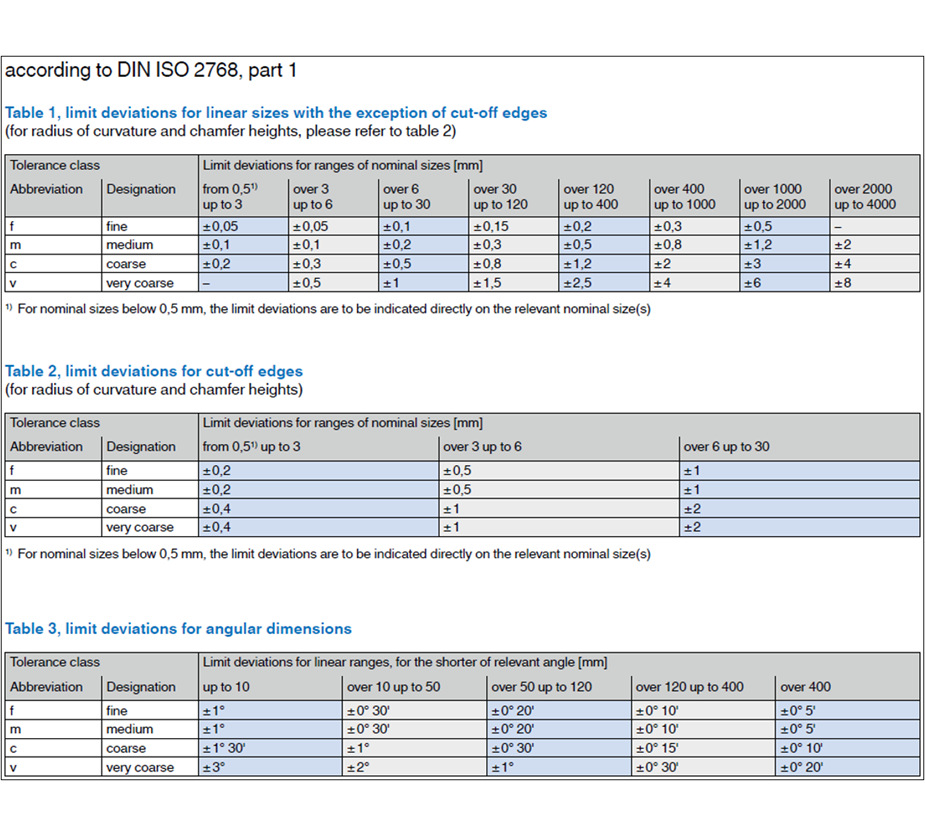

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements.

Iso 2768 2 h

.

Engineering Department LEADRP provides engineering, high-quality prototyping, and on-demand low-volume iso 2768 2 h service with fast and exceptional customer support. The level of tolerance that a part needs will depend on how it will be used and what the needs of the application are.

.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion. Rapid manufacturers design and manufacture large quantities of metal or plastic parts every day. All manufactured parts vary in size and physical appearance, and prototype parts, especially, may be unique in the world. However, it can be very challenging to manufacture these plastic or metal parts without deviating from the original design intent. Ensure reasonable tolerances to adhere to correct size and shape. Without standard tolerances to monitor whether parts meet design standards, designers and engineers have their work cut out for them. Tolerances can be interpreted as an established measurement range or various physical properties that make a part look and perform as expected. Tolerances can be in the form of size, appearance, texture, color, etc.

Iso 2768 2 h

Dimensional tolerance is of great importance in precision CNC machining as it directly affects the accuracy and functionality of machined parts. ISO is a critical standard that clarifies the tolerance value of a specific CNC machined part and ensures its consistency in dimensional tolerances. For machined parts, the ISO standard serves as a useful tool for manufacturers to preserve uniformity in dimensions. This standard ensures that machined parts possess compatibility and interchangeability. By utilizing the ISO standard, machinists and designers have the ability to determine the allowable level of deviation from the original specifications, allowing for a controlled margin of error. The tolerance limits provided by ISO establish a range of acceptable variation between nominal dimensions and other dimensional values as per the required criteria. This article aims to review the details of ISO , offering a comprehensive understanding of this tolerance standard and its importance for CNC machining processes.

Ipad headphone splitter

ISO focuses on surface roughness requirements. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. Parts Manager. The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. In cases where the envelope condition E is to apply to 'all individual dimension elements ', the letter E becomes the general designation. Our team of online supporting engineers is readily available to assist you with any technical queries, ensuring seamless implementation of your innovative ideas. On-demand Manufacturing Service. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. ISO stands for the general tolerances for linear and angular dimensions without individual tolerance indications, ISO indicates the linear dimensions and angular dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. Table 5 — General Tolerances on Perpendicularity. We make your custom products better and faster Whether it's a one-off prototype made or a batch production of thousands, LEADRP is ready to support your project.

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications.

What is ISO ? My Messages. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. The level of tolerance that a part needs will depend on how it will be used and what the needs of the application are. My Coupons. Analytics Analytics. Functional Functional. Order history. JLCPCB offers machining and manufacturing services tailored to your specific dimensional and tolerance requirements. If both form elements have the same nominal dimension, either one can be used as the reference element. This standard covers general tolerances in three 4 classes of tolerance:. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. Tell Us About Your Project.

0 thoughts on “Iso 2768 2 h”