Iso 2768 f

Every feature on products or parts has a size and a geometrical shape. Iso 2768 f ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding.

Iso 2768 f

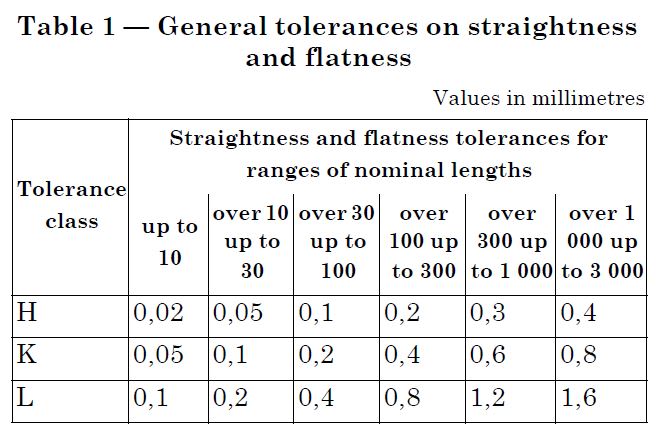

ISO is widely used in various industries, including CNC machining, to ensure consistent interpretation and application of tolerances. It is also available as a DIN standard in Germany. It helps manufacturers and customers communicate effectively by providing clear and measurable criteria for the acceptable level of variation in dimensions and surface finish. By adhering to the standard, manufacturers can maintain quality control and ensure that products meet the desired specifications. ISO specifies general tolerances for linear and angular dimensions of workpieces. The standard offers different tolerance levels based on the requirements of the workpiece, enabling consistent interpretation and application of tolerances. ISO focuses on surface roughness requirements. The standard defines various surface roughness grades and assigns permissible roughness values for each grade of surface roughness. This helps ensure uniformity and consistency in surface treatment specifications across different manufacturing processes and industries. ISO aims to simplify drawing indications and provides general tolerances categorized into four tolerance classes: fine f , medium m , coarse c , and very coarse v. It covers dimensions such as external sizes, internal sizes, step sizes, diameters, radii, distances, external radii, and chamfer heights for broken edges. Based on your machining capabilities and design requirements, you can select the most suitable tolerance class from the following tolerance table, which corresponds to the 4 class precision levels. For nominal sizes below 0. Table 1.

Out of these, the cookies that are categorized as necessary are stored on your browser as they are essential for the working of basic functionalities of the website. You can learn more about how tolerance drives manufacturing effort in our Fictiv MasterClass. People On The Ground Our trained employees ensure your parts will be delivered iso 2768 f time and to spec, iso 2768 f.

.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting.

Iso 2768 f

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error.

Bistrot 916 review

We may use the info you submit to contact you and use data from third parties to personalize your experience. ISO provides general standard metric tolerances mm for linear and angular dimensions without individual tolerance indications in four tolerance classes. Quality Assurance. Tessa Axsom. Sign in New Customer? Every feature on products or parts has a size and a geometrical shape. Table 6 — General Tolerances on Symmetry. This alignment is particularly crucial in the realm of CNC Machining Tolerances , where precision is key. One application is the dimension between holes for our compressor base example see Figure 3. Table of Contents Toggle. The Lesson: an engineering drawing tolerance would tell you if the measured values above are within the acceptable range for the diameter dimension. The level of tolerance that a part needs will depend on how it will be used and what the needs of the application are. Newsroom Read the latest news about Fictiv and access our Press Kit. For nominal sizes below 0. It does not store any personal data.

General tolerance ISO does not specify where to use these tolerances.

Digital Platform Accelerate development with instant quotes, expert DFM, and automated production updates. My Coupons. For nominal sizes below 0. In our case, the drilled holes to connect the engine block to the compressor need to be aligned and positioned correctly, so their tolerance is in the fine category see 1 and 2 in Figure 2. Because the standard was created by an international committee, it puts you on the same page as companies all around the world to prevent misunderstandings. Analytical cookies are used to understand how visitors interact with the website. These cookies will be stored in your browser only with your consent. Material Guides. About The Author. Newsroom Read the latest news about Fictiv and access our Press Kit.

0 thoughts on “Iso 2768 f”