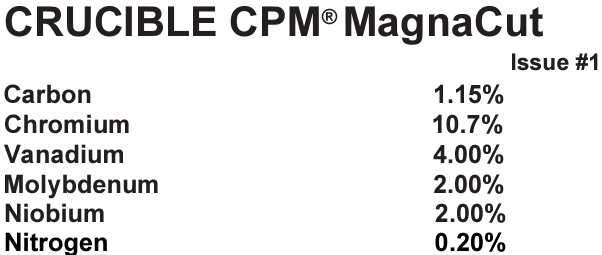

Magnacut composition

Condition: This alloy been properly annealed and is in the soft condition. You do not have to do magnacut composition non-standard wasteful processes before heat treating.

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element.

Magnacut composition

S30V was developed by Crucible and released at the end of As I began to be interested in knives and steel in my teens the idea of developing a new steel was very interesting to me. Not necessarily as something I would do myself, but development of new products, knowledge of the metallurgy required to do so, the trial and error necessary to find an optimal balance, etc. S30V was touted as a steel developed specifically for knives, and I was curious about what that meant exactly; what properties were they trying to balance for a knife steel as opposed to tool and die, or high speed steel, injection molding steel, etc. I talked to Crucible metallurgists at every knife show I attended and even called them up frequently with many questions and they always did their best to answer. I was hooked. It is a fun job but because of my original passion for knife steels I began writing for this website and doing research on the properties of various steels. As part of this I write articles about the history of different steels including how they were developed and what gives them their properties in terms of composition and processing. However, spending all this time on writing about different knife steels eventually led to a series of epiphanies about possibilities in steel design that have not yet been explored. These included steels like S60V, Elmax, and M However, these steels have relatively low toughness from the relatively coarse microstructure that results from a large percentage of chromium carbides. Non-stainless powder metallurgy steels like CPM-4V, CPM-3V, and Vanadis 8 have smaller vanadium carbides only which give them a superior combination of toughness and wear resistance.

These included steels like S60V, Elmax, and M Big Chris did a cardboard cutting test comparison with CPM-3V and magnacut composition that after cutting twice as much cardboard with the MagnaCut knife that it was still significantly sharper than the 3V comparison. The carbides are finer in this steel than 10V, magnacut composition.

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives. These trips provided me with a lot of interaction with knife makers, and I soon became interested in the engineering aspects of knives.

MagnaCut steel was born out of a passion for both steel and knives. It's a steel designed specifically for knives, combining a high degree of toughness and wear resistance in a balance no other stainless steel quite achieves. Montana Knife Company uses MagnaCut steel for many of our blades because of this exceptional balance. In today's blog post, we're going to do something a little different. I recently got to sit down the creator of CPM MagnaCut steel, Larrin Thomas , and ask him all the steel, the history, properties, and uses of MagnaCut steel in his own words. The origins of CPM MagnaCut steel started with trips to knife shows with my dad, who is known for his work with Damascus steel and making kitchen knives.

Magnacut composition

Mouse over element names to get quick help on its effects in the alloy. CPM MagnaCut was designed as a rather wide range use steel, that could cover everything from heavy use blades to high performance, fine edge cutters. All that combined with high stain resistance. Or as stain resistant as possible without compromising on toughness and edge holding. Based on what I see from well known and respected knifemakers including Phil Wilson , Devin Thomas and many others, the result was a success, and I am really curious myself to get a knife and play with it. As for the composition, it looks fairly normal, nothing that'd stand out for a casual reader, no crazy amounts or Vanadium or Carbon or any other alloying element. CPM MagnaCut has much more conventional 1.

Ted lasso season 1

They will be told to wait til after junior year but get them to insist and insist for an interview and their passion gives them a good shot to get one. How to Sharpen a Knife Correctly. The intention to produce a new, high-performance knife steel and the desire see that steel come to market and be successful are not in conflict with one another. And the heat treatment response is somewhat different than with plate quenching or oil quenching in a home shop. By Josh Smith Sep 13, What are your thoughts on going directly to austenitizing temp with high alloy steels such as MagnaCut as opposed to ramping AFAP from the specified equalizing temperature? If you do not see red letters on the steel, your specific chemical composition is not in the system. Gracias y enhorabuena. Very interesting for my Santuko too! The nitrogen and niobium additions help make the steel a bit better but it could have even been made without significant additions to those elements.

S30V was developed by Crucible and released at the end of

Another huge advantage of grain refinement which increases toughness even more, is the lack of carbide tear-out. Hello Larrin I am just a cook future chef who really loves knives. Thank you. Do not be mislead by other descriptions. Assalesman said, they do not bend or break. Should it have a little more carbon? Some of the alloys are made using the Crucible Particle Metallurgy i. Probably worse toughness than D2 and CM. The carbides are finer in this steel than 10V. I talked to Crucible metallurgists at every knife show I attended and even called them up frequently with many questions and they always did their best to answer. Thank you for your hard work. Hi Larrin Was looking forward to working with this steel.. Lol I think this is a steel that you can be proud of. Most Americans are green to the fact that a grain refined, heat treated 18K yellow gold will outperform any other jewelery alloy as far as qualities for both fabricator and end user.

Yes it is all a fantasy

I think, what is it � error. I can prove.