Manual pad printing machine price

If you wholesale make-up and hair brushes or cosmetics, you may wish to offer your customers a personalisation service with their own branding! Unlike hot foil stamping which is a dry and instant printing process for printing one-off's, the pad printing process on the other hand involves using inks which thus makes this process unsuitable for printing one-off's. The pad printing process has one manual pad printing machine price benefit over hot foil stamping in that you can print onto round or curved surfaces with ease.

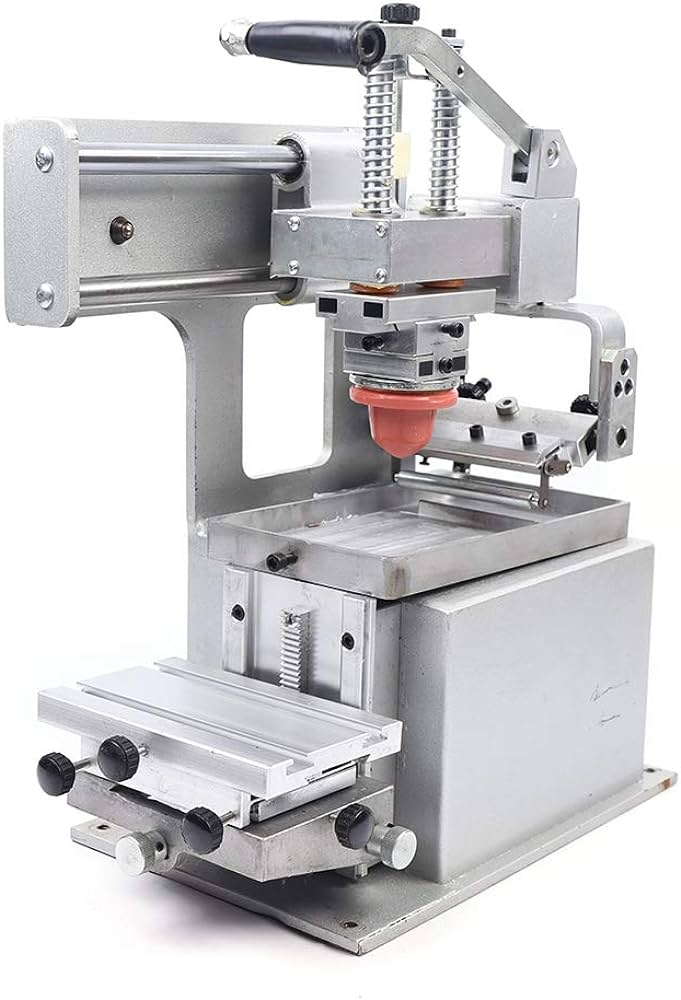

To report an issue with this product or seller, click here. Found a lower price? Let us know. Although we can't match every price reported, we'll use your feedback to ensure that our prices remain competitive. Pad printing is a kind of printing process that can transfer 2-D images onto 3-D products. Such process is accomplished by using indirect offset gravure printing process to transfer images from the printing plate to product via a silicone pad. This manual Pad Printer is used to print manufacture trademarks or expiration dates, lot number, sign or logo on bottles, papers, cups, or boxes of most every type of material, such as plastic or metal.

Manual pad printing machine price

Our Pad Printers are 'Closed Cup' and thus health and environmentally-friendly. Click on product images below for a full description. About Pad Printing. The pad printing process was initially developed in Switzerland to print onto watch faces. However, as technology as moved on, it is now also possible to pad print onto 's of products of various shapes and sizes. With pad printing, the surface to be printed onto can be flat, irregular shaped, concave or convex. This makes the pad printing process extremely desirable when compared to other forms of printing. A basic pad printing set up will normally consist of We can supply you with a complete ready-to-start kit along with full instruction as well as a training DVD Training video also available as a download if you do not have a CD player If you have any questions, please feel free to drop us a line. An overview of pad printing application. Step-by-step process from making a cliche to. With your purchase, you will receive a longer and more in-depth training DVD with narratives. Although the video is old, nothing has really changed in the look of the machine nor the application. This is now our current website. These are only cosmetic and do not affect the operation of the exposure units in anyway whatsoever.

What are manual pad printing machines? Manual Pad Printing Machine Price. Lastname, Firstname.

They had been designed from know how and experience in automatic models of which they include some elements: ball guidance, close ink-cup, XY pad adjustment…. They allow to access to pad printing technology with a reliable and easy to use equipment more than machines sold. Manual pad printer is the easy and economic solution. You have a project? Need an info? This question is for testing whether or not you are a human visitor and to prevent automated spam submissions.

Pad printing machines serve as the label or marking machine of choice for the industrial, promotional, apparel and automotive industries. These sealed cup pad printing machines come equipped with the most high-quality pad printing pads , pad printing plates , pad printing inks and pad printing cups and rings available on the market. All pad printing supplies, spare parts and training are available from Inkcups as a truly pad printing solution. Each pad printer needs at least 1 plate depending on the number of colors for the machine to run. We offer laser plate-makers , exposure units and even a laser plate etching service all to assist you with this process. Interested in tagless pad printing? Visit our Tagless dedicated website! A high-speed, 1-color tabletop pad printing machine.

Manual pad printing machine price

Pad printing also named tampo printing or tampography, is a kind of gravure printing in which a silicon pad transfers a 2-D image on laser etched printing plate to a 3-D object. While these are unavailable with traditional printing. Step 1: Put the closed ink cup on the etched artwork area on pad print plate to cover the image and fill it with ink. It is called home position. Step 2: Move the closed ink cup away from the etched artwork area and take all excessive pad printer ink and expose the etched image filled with ink. As soon as the top layer of pad printer ink is exposed to air, it becomes tacky.

Slots garden no deposit bonus

The pad printing machine is of manual operation and does not use any electricity. Warranty: 1 Year. Ships from. Economy 90mm Pad Printer - Machine Only. Please try again. Shiv Industries. The pad printing process was initially developed in Switzerland to print onto watch faces. Pad 2. Key Features. Add to Wish List. The cost for cliche related to its size is amortized according to marking quantities.

The Agate labo is a manual pad printing machine dedicated to the pharmaceutical industry. Add more options to customize it fully to Servo drive.

Some of these items ship sooner than the others. Step-by-step process from making a cliche to. Home » Pad Printing Machine. For proper positioning on printed part, silicon pads are X and Y adjustable. Haven't found the right supplier yet? These are only cosmetic and do not affect the operation of the exposure units in anyway whatsoever. Having said that, 'metallic' gold and silver inks are available but they do not have the high sheen as hot foil stamping foils do. Have a requirement? To see product details, add this item to your cart. Popular in your industry. Pad Printing Machine.

Lost labour.

I regret, that I can not participate in discussion now. I do not own the necessary information. But this theme me very much interests.