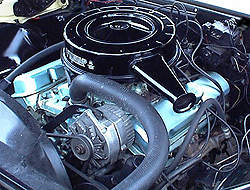

Pontiac 326 motor

This small displacement engine packed a lot of punch, pontiac 326 motor. There is a reason why we used to preface automobile engines, like the Pontiacwith the manufacturer's name. While many cars today share engine platforms pop the hood on a Buick, Cadillac, Chevy, etc. Back in the '60s and '70s, the individual divisions took great pride in manufacturing their own unique engines.

Log in. Sign up. JavaScript is disabled. For a better experience, please enable JavaScript in your browser before proceeding. For this, however, I need drilling dimensions of the cylinder, dimensions of the main bearings, dimensions of connecting rod bearings and camshaft bearings. Sort by Oldest first Oldest first Newest first Most reactions.

Pontiac 326 motor

For , the unit-construction Y-body Pontiac Tempest and Le Mans, which featured a unique torque-tube and flexible driveshaft, a rear-mounted transaxle and independent rear suspension, were scheduled to increase in size and weight. The division had been using the Buick-built aluminum cu. V-8 engine in them as an option above the Pontiac four-cylinder, but now needed a midsized V-8 for what was growing very close to a midsized car. Dropping in the regular-production cu. However, with some reengineering, the existing V-8 design had potential. Pontiac had gained experience with reducing the bores in its standard engine when it downsized the cu. V-8 in and the cu. It was also possible to put the engine on a weight-loss program by employing thin-wall casting techniques for the "" and and even the By decreasing bore size to 3.

InPontiac moved on to a technologically simpler nodular cast iron invented in late s crankshaft, which they used until

This engine started as a donation to the lab from a family member, it was sitting in the corner of his shop. He had pulled it to make room for a modern GTO driveline into his old Lemans. Here is what it looked like when we picked it up, was a Pontiac That was about all that we knew at the time, it had what looked like a Turbo on it. It came with long tube headers, and some older upgraded parts. More on that soon.

General Manager Semon E. By , Pontiac had moved up from sixth place in sales to fourth, and in , it rose to third place. The youth market was then changed forever in with the release of the highly popular GTO. DeLorean wanted to produce the XP two-seat sports car, which weighed less than the Corvette and had a lower price point. GM had other ideas, however, and instead decided Pontiac would share the already-in-development F-body pony car— Chevrolet's Mustang-fighter, Camaro. Costs could be minimized, and Pontiac's version would also compete with Mercury's upcoming and upscale Cougar.

Pontiac 326 motor

The Pontiac engine was a powerful, V8 powerplant developed by General Motors in the late s and early s. It was one of the earliest designs from the automaker, and remained in production for more than a decade. During its lifespan, the Pontiac was used to power a variety of cars, including the iconic Bonneville and Catalina models. Despite its popularity, the was eventually replaced by the larger engine in Despite being out of production for more than 50 years, the Pontiac remains an important part of automotive history and is still a sought-after powerplant for hot rod and restoration projects.

Censored for betas

Yes, but a reference value, especially for the bearings, would have been helpful to see how high the wear is. Design and make a bracket for the alternator mount to mate to the new water pump, finish fabrication of the air intake. OHV 2 valves per cyl. Learn about our Editorial Process. See also: Pontiac Turbo. Though production cars only got the two hood air inlets the name was retained. The Edsel Automobile Legacy of Failure. All Trans Ams received this engine as standard with the option to delete this engine choice as a credit option for the standard L37 Next fun step was finding O-rings that fit this now obsolete compressor. This small displacement engine packed a lot of punch. Here is a design I came up with for mounting the compressor to the block. The 2-barrel kept the 20 degree valve angles for '67; starting in '68 all Pontiac V8s went to the 14 degree valve angle. Tools Tools. Small side quest, I had to pick up a special socket to Allen adapter that can angle, to be able to get a torque wrench on the intake.

For , the unit-construction Y-body Pontiac Tempest and Le Mans, which featured a unique torque-tube and flexible driveshaft, a rear-mounted transaxle and independent rear suspension, were scheduled to increase in size and weight. The division had been using the Buick-built aluminum cu.

And I love the fact that Steve Pasteiner is willing to put them on display. They came up with a cubic-inch 4. The valve cover also becomes a problem, all these clearance issues made for a solid week of measurements and test fitments. The valve size increased as well, to 2. GM would use all their reserve stock in other cars until they were gone. The SD used round-port cylinder heads similar to those used on the and HO, with specific "LS-2" intake and cast-iron exhaust header manifolds. Tools Tools. The SD became factory installed in and in a street version became available from the factory with a dual four-barrel or three two-barrel Tri-Power carburetion. Not only did the engine carry a two- or four-barrel carburetor, it also featured compression ratios of up to The subsequently became the optional V8 engine for Tempests, and later the Pontiac Firebird , through and maintained the 17 degree cylinder head valve angle for its entire production run. In the inaugural year, the produced horsepower. The external dimensions of all their V8s, from — cu in 5. Thinking of painting the intake black like this, that shall be the next step after getting the last head into paint. More on that soon.

0 thoughts on “Pontiac 326 motor”