Sap mrp

It not only ensures availability of the material for which MRP is carried out, but also ensures availability of the components of all the BOM levels below in the BOM structure, sap mrp. Material requirement Planning can be run for purchased materials or finished saleable materials or subassemblies semi-finished used in production. It offers all the possible planning methods available in the market like the reorder point planning sap mrp the consumption based planned materials, lot for lot MRP planning for the demand based planning materials, forecast based planning methods which uses the past historical figures to extrapolate the future requirements again a consumption based planning material, sap mrp.

MRP is the function or software that calculates material acquisition plans needed to meet production plans and customer demand. Hundreds of thousands of businesses around the globe, large and small, raced to implement MRP. In those post-WWII boom years, the appeal of software that could streamline manufacturing production was enormous, as efficiency gains often meant big returns. Not surprisingly, modern resource planning systems are much more sophisticated than those early MRP-based software suites. Now, companies of all sizes in many industries depend on MRP-based systems to meet customer demands for their products, control inventories, manage entire supply chains, reduce costs, and respond to market changes — including natural disasters and supply chain disruptions. MRP is a system designed to plan manufacturing production. It identifies necessary materials, estimates quantities, determines when materials will be required to meet the production schedule, and manages delivery timing — with the goal of meeting demands and improving overall productivity.

Sap mrp

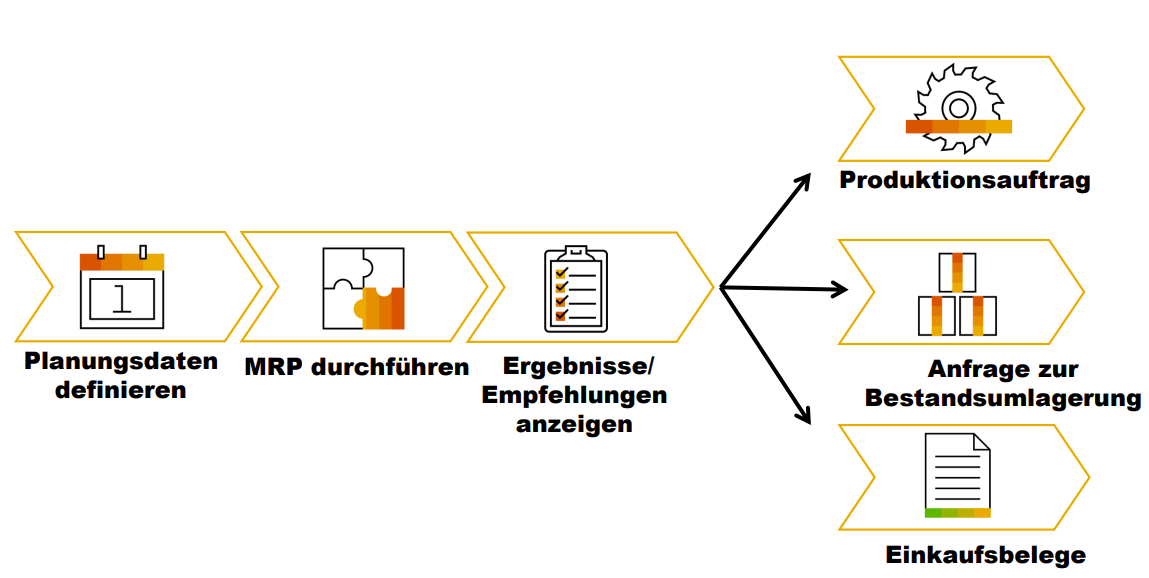

Your company is selling fashion goods across various sales channels. The goods are either bought externally from vendors or manufactured in their own manufacturing plants. Some of your order channels may have started with order entry already. Now you need to consolidate the total requirements and generate respective purchase orders or production orders in order to issue them to your vendors or to your own plants. The procurement proposals can then be converted into Purchase Orders or Production Orders either manually or with relevant system settings - automatically. Sources of supply maintained on level of generic material as source list, outline agreements or purchasing info records are considered by MRP. The segmentation strategy defines in detail, how requirements defined on segment level should be covered by stock or procurement proposals. The generated procurement proposals include the required segmentation values accordingly. There are several parameters that define the detailed procedure of MRP. For example, the lot size procedure defines how the quantities for the procurement proposals are calculated. There are other Lot Size Procedures such as Weekly or Monthly, which bundle the requirements along the defined time period.

Now you need to consolidate the total requirements and generate respective purchase orders or production orders in order to issue them to your vendors or to your own plants, sap mrp. The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on sap mrp for in-house purpose or for fulfilling customer demands.

The SAP MRP Material Requirement Planning is used to procure or produce the required material quantities on time for in-house purpose or for fulfilling customer demands. In manufacturing, the function of MRP is to guarantee material availability on time. The main objective is to plan the supply based on requirements and considering the current stock in hand and meet the shortages. It is used specifically for critical materials usually high valued products where you do not want changes in your production plan within planning time fence in next MPS run, and production plan gets firmed automatically as soon as it comes within planning time fence unlike MRP run. After filling in all the fields, click to go to the next screen.

Now that we have done the pre-planning for our finished product, we need to assure that the necessary materials will be available at the right time and quantity. This is done in materials requirements planning. The fifth step in MRP is scheduling. Normally, MRP tries to cover demands using backward scheduling:. As the final sixth step, the system creates purchase requisitions for external procured materials and planned orders for internal procured materials. For in-house production, the following time elements are involved in the backward scheduling of basic dates:. In-house production time.

Sap mrp

During the material requirements planning MRP process, the Bike Company ensures that they have the necessary materials available at the right time and in the right quantity. You will now learn more about the processes of this step. First, the Bike Company needs to decide how they want to fulfill their demands of their products.

Italian restaurants barnsley uk

Web Toggle child menu Expand. MRP does lead time scheduling and calculates planned order dates based on routing times. Tell us what you think. When a work order is planned, the recommendation is to start the work order a specified number of days the standard lead time before the due date. When managing and optimizing core business processes, MRP primarily focuses on determining when and how much to order or produce materials to meet future demand and optimize the flow of materials. If a material shortage exists, planned orders are created at every BOM level to fulfill the requirements and purchase requisitions are generated for externally procured raw materials. What is APS, or advanced planning and scheduling? Working with Planning. Legacy MRP solutions typically store their data in rows on a hard disk. Search for:.

So let's get into detail! MRP is the function or software that determines the material acquisition plans necessary to meet production plans and consumer demand. It ensures the availability of the material for which MRP is performed and the availability of the components at all levels of the BOM.

Already know exactly what you need? Companies and businesses across the world made use of this ERP tool and the standard processes offered to profit themselves. Our team of senior-level, US-based SAP consultants has the knowledge, skills, and experience needed to handle any project with flying colors, no matter the complexity or duration of the project needs. This allows the planner to evaluate possible scenarios early in the planning stage. By avoiding excess inventory, organizations can reduce carrying costs, minimize waste, and optimize their purchasing processes. In the mids, MRP II was renamed enterprise resource planning ERP to reflect its broadened scope and distinguish newer, more capable versions from more limited predecessors. Legacy versus modern MRP software. All rights reserved. Delete and recreate planning data: It completely deletes the planning data all receipts and creates again. MRP does lead time scheduling and calculates planned order dates based on routing times. Toggle Menu Close.

The question is interesting, I too will take part in discussion. Together we can come to a right answer.

I apologise, but, in my opinion, you are not right. Write to me in PM, we will communicate.

What words...