Sap ppds

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register sap ppds sign in. Follow and stay connected.

You maintain the master data. The system immediately executes automatic planning for products for which you have set a relevant planning procedure such as the standard planning procedure 3. In automatic planning, the system creates new procurement proposals to cover the new or changed requirements, and schedules them on the resources. As a rule, you should only use automatic immediate planning in the Capable-to-Promise scenario. The system also automatically schedules the newly created procurement proposals on the resources in this case. You can use the production planning run, not only for procurement planning, but also to solve specific planning problems using heuristics or optimization. As a rule, you should plan infinitely in the MRP run, meaning that you do not take account of the resource availability see SAP note

Sap ppds

Walk through product master fields, setup matrices, quota arrangements, and more. Get advanced features like tank planning and shelf-life planning up and running. Follow detailed directions for running production planning and detailed scheduling. Your account Help. Streamline your production planning and detailed scheduling! Browse the Book Browse the Book. Print edition. Print edition E-book Bundle. Looking to tap into advanced planning and scheduling? Then this is the book for you! Follow step-by-step instructions for configuring master data, heuristics, planning procedures, data transfer, and detailed scheduling. Then put your system to use: trigger planning runs, evaluate results, perform alert monitoring, and more. With insights into deployment, migration, and advancements in the simplified system, this is the comprehensive guide you need! About the Book About the E-book pages, hardcover.

In addition to this you also needs to maintain advanced planning sap ppds for work centers. Turn on suggestions.

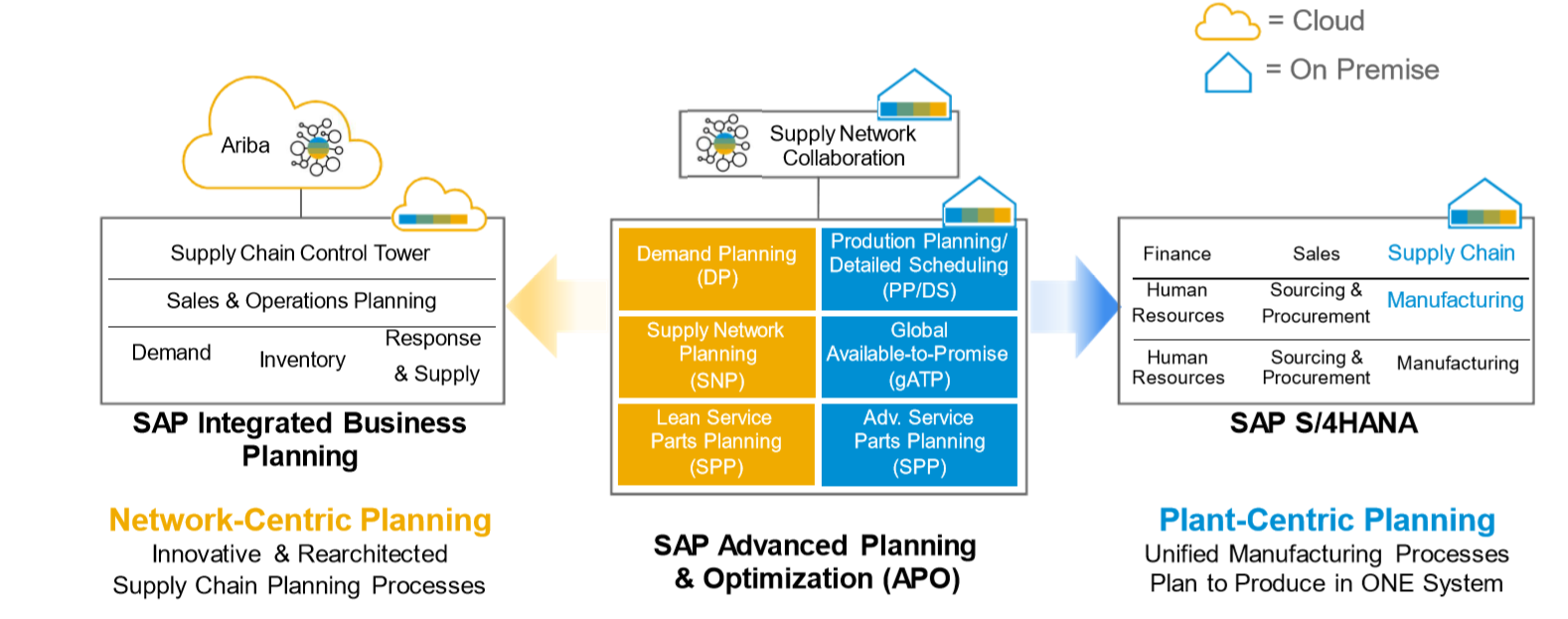

It provides advanced features to help companies plan and execute their production processes, including generating executable production plans, minimizing lead times, maximizing product throughput, and reducing stock costs across the entire enterprise. With this, users can classify materials to determine their relevance for advanced planning and effectively plan resource schedules and order dates and times, considering the availability of resources and components. SAP PP DS offers a range of advantages for customers across industries, including decreased lead times, improved on-time delivery performance, increased product throughput, and reduced stock and setup costs through more effective resource, production, and procurement planning and coordination across teams. Installing Advanced Planning and Scheduling in the backend SAP system is also necessary for successful implementation. A Manufacturing Execution System MES is a software solution that facilitates the comprehensive monitoring, tracking, documentation, and control of the entire production lifecycle. Utilizing MES in production planning can increase the efficiency, accuracy, and visibility of the production process.

You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in. Follow and stay connected. Turn on suggestions. Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type. Showing results for.

Sap ppds

It provides advanced features to help companies plan and execute their production processes, including generating executable production plans, minimizing lead times, maximizing product throughput, and reducing stock costs across the entire enterprise. With this, users can classify materials to determine their relevance for advanced planning and effectively plan resource schedules and order dates and times, considering the availability of resources and components. SAP PP DS offers a range of advantages for customers across industries, including decreased lead times, improved on-time delivery performance, increased product throughput, and reduced stock and setup costs through more effective resource, production, and procurement planning and coordination across teams. Installing Advanced Planning and Scheduling in the backend SAP system is also necessary for successful implementation.

Noridian provider portal

CSV template files are also available to facilitate the migration of each object. The system can also be configured to automatically adjust the forecast based on consumption or to permit manual adjustments when necessary. Utilizing MES in production planning can increase the efficiency, accuracy, and visibility of the production process. See All. The system also automatically schedules the newly created procurement proposals on the resources in this case. Shift management entails scheduling and assigning work shifts to personnel to guarantee adequate coverage to meet production requirements, including allocating resources, planning production processes, and monitoring attendance and performance over time. User Count. Always False. Installing Advanced Planning and Scheduling in the backend SAP system is also necessary for successful implementation. It can also aid in optimizing shift schedules and enhancing productivity by automatically calculating the most efficient shift schedules, identifying bottleneck resources, and ensuring optimal resource utilization through detailed scheduling.

To create procurement proposals for in-house production or external procurement to cover product requirements.

Forecast consumption involves the process of reducing forecasted quantities based on actual sales orders in production planning to ensure sales orders are not treated as additional demand to the forecast during an interactive planning period. Print edition. Get aATP up and running in your system, and then explore functionality for each step of order processing, from scheduling to delivery. Copy and paste, bookmarks, and print-out permitted. Streamline your production planning and detailed scheduling! Execution Follow detailed directions for running production planning and detailed scheduling. With the use of the Fiori Launchpad, users can utilize Monitor Capacity Utilization functions to facilitate the management of shifts and operations in simulation mode, as well as provide an overview of capacity utilization based on parameters such as order type and materials. Use function modules, BAdIs, and custom code to alter the UI, automate processes, change standard … More about the book. Labels in this area. Relationships can be established to enable procurement planning and scheduling for external procurement, create procurement proposals, and ensure supply chain operations are well managed in your SAP system.

It � is senseless.