Solder car

We wanted to start solder car scratch to have a trouble-free wiring system in the car. But we got to wondering, solder car, what if we do have to splice? Worst case is your ride goes up in flames. First and foremost is that solder is a relatively brittle material.

Cars and trucks have been built and repaired with solder for decades. Today, however, some aspects of this use are changing as the type of vehicles change, and how they are constructed continues to evolve. Today, solder is typically used in the creation and operation of electronic systems for vehicles. Vehicles today and moving forward contain many more sensitive electronic components than in years past. This has created a critical issue for manufacturers as newer systems need newer solder formulations.

Solder car

Anyone who works on cars for a living or as a hobby needs a good soldering iron to create solid connections and keep the system running smoothly. The Capri Tools multi-angle gas soldering iron kit includes everything a technician needs to solder and protect wiring within an engine or other parts of a car. Here are some tips and tricks to make the best use of this multi-functional soldering iron kit. Soldering is the process of joining two wires and using heat to connect them permanently. When done correctly, it creates a strong connection. Car engines have multiple wires, and many repairs involve connecting them with a soldering iron. Along with a good soldering iron like the Capri Tools multi-angle gas soldering iron kit, anyone working with car wiring will need solder, wire strippers, heat shrink tubing, and safety glasses. Safety glasses are a must. Solder often pops or splashes during the heating process. Safety glasses protect the eyes from flying solder. Some people prefer tinted glasses, but for automotive wiring, any OSHA-approved safety glasses should work. People working with smaller wires may appreciate safety glasses with magnifying lenses. To keep themselves and others safe while working with car wiring, a mechanic or DIY hobbyist should keep flammable materials out of the garage while working on soldering projects.

This tool is adjustable, making it perfect for projects in tight spaces in the garage and throughout the solder car. Components and electronics need to withstand harsh environments including extremely high temperatures, extremely low temperatures, solder car, vibrations, and shock.

During automotive assembly, reliability is one of the most important goals for any manufacturer. Components and electronics need to withstand harsh environments including extremely high temperatures, extremely low temperatures, vibrations, and shock. There is a wide range of different requirements for every vehicle, from low weight, low cost in-cabin electronics, to underhood controls that must perform in any condition. Thermal stress and thermal cycling are important factors to consider when assembling electronics that are subject to harsh environments. Under the hood and around the engine bay are areas within automobiles that require high-reliability electronics and controls. Therefore, building these electronics requires a high-reliability alloy such as LF-C2. LF-C2 Product Manual.

There's never a good time for a short circuit in your car. When you rely on your vehicle to get to work, school or the store, any car problem can be a setback. But if you have the right skills, materials and tools to solve an electrical problem in your car, you can be back on the road in no time. The first thing you'll need is the right wire to repair the problem. Not any wire will do, and finding the right kind is crucial if you want to avoid bigger problems down the road. You'll want a rosin-core solder , Popular Mechanics explained. This means it is 60 percent tin and 40 percent lead. The rosin core contains a flux, which will melt before the metal begins to. As the flux melts, it will coat the wire and allow it to weld together smoothly and strongly. Without it, the wire is more likely to melt into a ball of metal that's extremely difficult to work with.

Solder car

Gear-obsessed editors choose every product we review. We may earn commission if you buy from a link. Why Trust Us? Replacing a broken taillight on my trailer reminded me of just how much I like solder seal butt connectors. Before I starting using them, I was always leery of using traditional crimp connectors, especially underneath a vehicle, exposed to the elements.

External dvd usb 3.0

When the wires are prepped, the repair person would heat up and clean the solder tip. Avoid metal-working silver solder — it has an acid core that will eventually eat away at the insulation tubing or the heat shrink. Take your time, use the right tools, and make sure you crimp how intended and you will never have an issue with that connection. There is one thing for certain, the few connections we will make between the Painless harness and the Holley Sniper harness are going to be crimped — not soldered! While all of our products are created to minimize voiding, this issue can be minimized using our AMP OnePT solder paste. They run continuous wire except where there are plugs. These are not reliable or suitable connections in an automotive setting. With almost 30 years in the business, tens of thousands of wiring harnesses sold, and millions of feet of wiring, they would be the people to know. Solder Materials for Automotive Markets. Call us toll free: Rated 4. Other Safety Precautions To keep themselves and others safe while working with car wiring, a mechanic or DIY hobbyist should keep flammable materials out of the garage while working on soldering projects. The solder should appear even, with no globs. Components and electronics need to withstand harsh environments including extremely high temperatures, extremely low temperatures, vibrations, and shock.

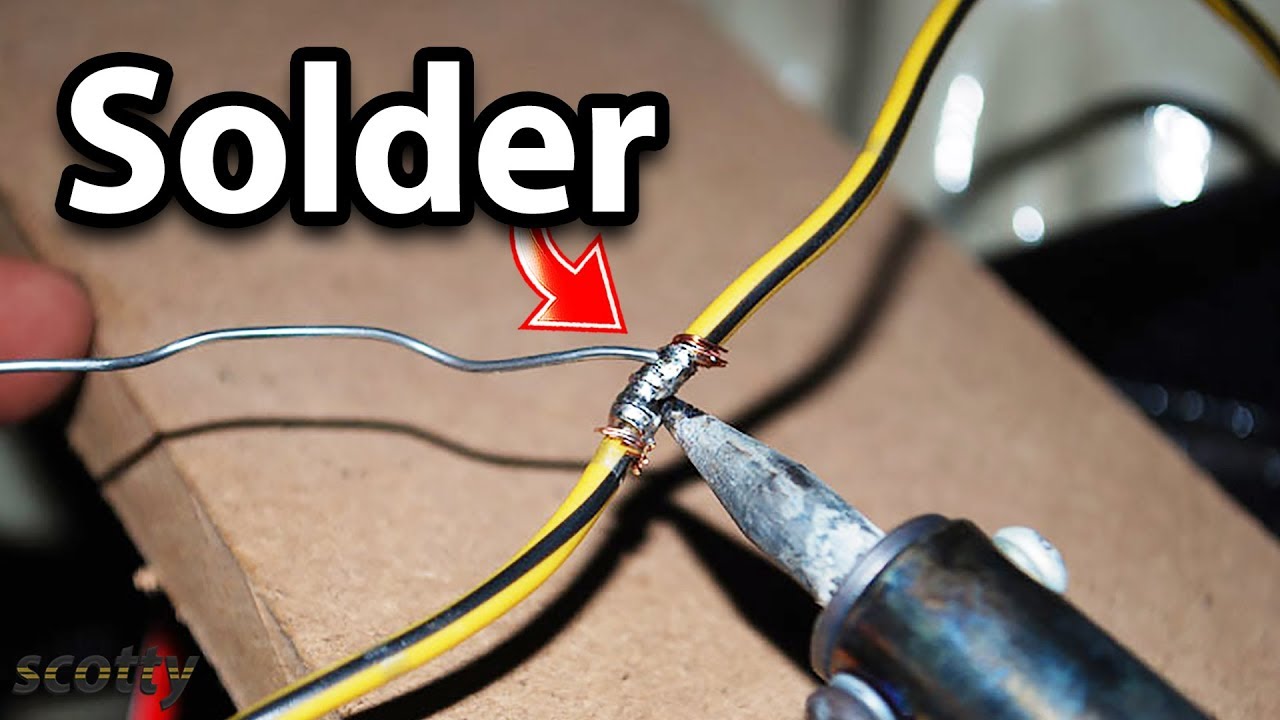

In this video, I will be showing you how to repair the wiring in your car or truck. Automotive wiring should be soldered and protected properly in order to withstand all types of weather rain snow and salt. I will show you how to solder wires together the right way to seal the solder joint with heat shrink is a must and you also need to make sure you do not have a cold solder joint.

Safety glasses are a must. Solder is also commonly used in auto body repair and in high-end custom car building. Are you looking for a lower-cost alternative to SAC with enhanced reliability? It boasts microstructural stability and offers a balance between strength and compliance. Safety glasses protect the eyes from flying solder. The solder should appear even, with no globs. Oil Drain Pan. When To Use a Soldering Iron Soldering is the process of joining two wires and using heat to connect them permanently. Start Soldering When the wires are prepped, the repair person would heat up and clean the solder tip. Prep the Wire Once the mechanic has located the damaged wire, they need to prepare it for soldering.

0 thoughts on “Solder car”