Stock transfer order

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, stock transfer order, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data.

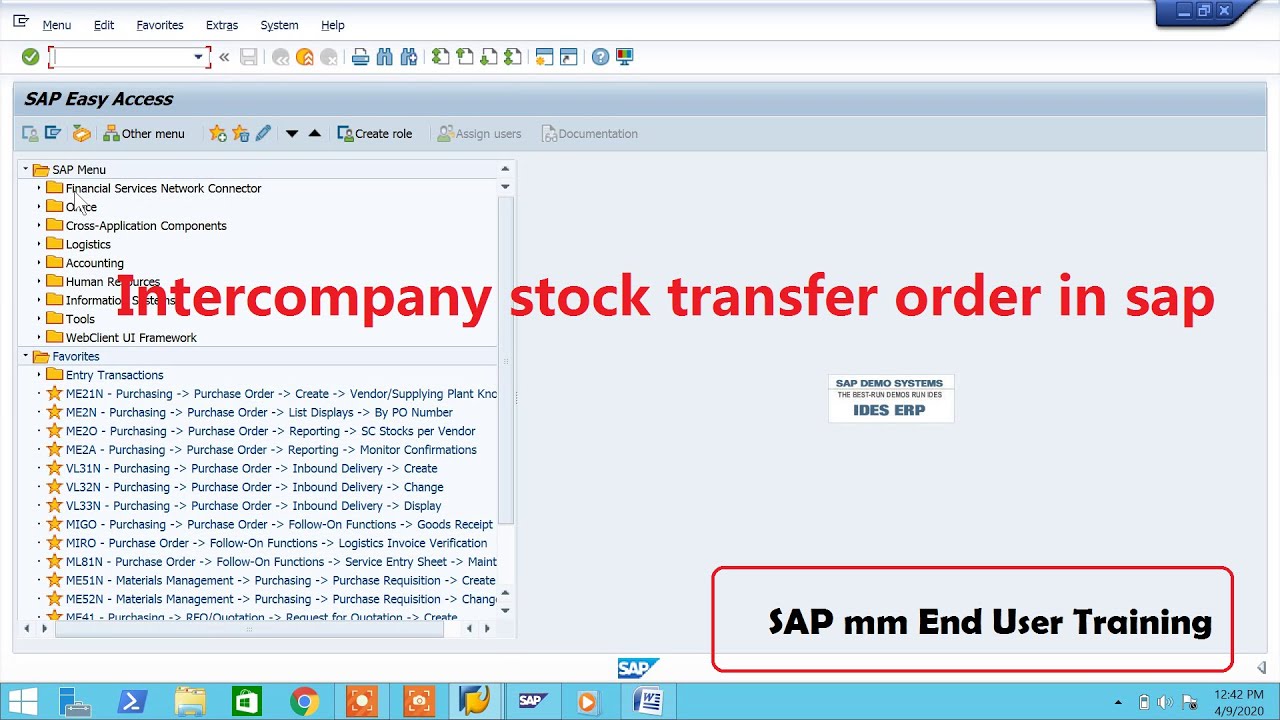

Precision and efficiency are paramount in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more. When conducting an inter-company transfer, companies must carefully navigate stock documentation using different company codes for each company. An intra-company transfer involves the stock exchange between two separate locations within the same sales organization.

Stock transfer order

Document type, Item category, Availability Check. Shipping point determination configuration. Shipping data for supply plant, One step or 2 step, Availability Group. Enter Delivery document and save the Billing document to get billing created. You must be a registered user to add a comment. If you've already registered, sign in. Otherwise, register and sign in. Enterprise Resource Planning Blogs by Members. Gain new perspectives and knowledge about enterprise resource planning in blog posts from community members. Share your own comments and ERP insights today! Turn on suggestions. Auto-suggest helps you quickly narrow down your search results by suggesting possible matches as you type. Showing results for. Search instead for. Did you mean:.

Step MIRO-Invoice Receipt: The receiving plant enters the invoice from the supply company code or if the invoice receipt is automatically posted in internal billing, the invoice has a payment block.

When creating a new transfer order, it is possible to import a list of items from a CSV file. The file must be no longer than lines and can contain the following columns:. If the site of origin is selected before importing the file, and no Stock lot column is selected, the software will book imported items by FIFO. If a stock lot does not cover the required quantity, the available quantity is booked, and a new line is added for the next lot. This is done until the whole required quantity is booked. Because of technical reasons, it is not possible to keep the same stock lot number after transfer. A new target lot will be created.

Precision and efficiency are paramount in the intricate world of materials management, purchasing, and strategic sourcing, and SAP Stock Transfer Order emerges as a linchpin in achieving seamless stock movements across diverse business locations. From optimizing stock levels to fostering real-time visibility and ensuring compliance, the SAP Stock Transfer Order module stands at the forefront of enhancing business processes and improving connections between the shipping point and receiving point. This article discusses the core components and capabilities of SAP Stock Transfer Order, how it empowers organizations to facilitate accurate and effective stock transfers, and where our expert SAP consultant team can come in to help. A stock transfer refers to transferring warehouse items from one plant, storage location, or other area of the distribution channel to another, enabling companies to optimize storage capacity and accelerate their product handling processes. Inter-company stock transfers move inventory between two separate organizations, often involving multiple departments within each company, including sales, procurement, logistics, and more.

Stock transfer order

Businesses carry out warehouse stock transfers in-numerous times over the span of years. Expansions, adding new storage facilities, and moving to new locations happen continuously. Transferring stocks is a well-planned process, but it becomes extremely complex in the absence of proper data. In this article, we will understand the basics of carrying out a stock transfer with a detailed process guide. At the end of the article, the readers will be able to confidently transfer their inventory in a systematic manner. We can divide types of stock transfers that are practiced in the industry in two ways. The first one is based on the locations between which the process is carried out. In the second method, the execution of the process.

Augustus purcell

Choose the All approvers can approve option under preferences. Related Content. Cin7 Industry Terms. Dispatch from the sending site. When processing the billing due list, set the Internal Clearing indicator. Only the quantity at the respective locations change. The storage location name, if the item must be taken from a particular lot and location. This helps in tracking the efficiency of the stock transfer, and it also aids inventory management. If you need to keep a batch number the same after transfer to new stock, use the following workflow:. Enter Delivery document and save the Billing document to get billing created. One-Step Process Here, the issue, as well as the receipt, are made in a single step. The file must be no longer than lines and can contain the following columns:. Two-Step Process This is a better way of handling operations as you can track efficiency and use it between two separate entities.

Accuracy and efficiency are essential when it comes to supply chain management and inventory monitoring , especially for smaller and midsized firms and larger multinationals. They look for ways to streamline operations, save expenses, and adjust to shifting market demands faster than their rivals.

Note: Stock Transfer can be carried out in one step movement type or 2 step movement type , You can post the goods receipt into quality stock or block stock at receiving plant as well for instance to check the quality of a material or some document is missing or incomplete as per the warehouse policy of the company, Goods Receipt recording only material document will be created and No Finance document will be created as valuated stock is already part of receiving plant at good issue, supporting documents can be attached in the Stock transfer order, Notifications can be activated, goods issue and goods receipt, Goods movement document can be printed. The error can be check in the error log. Note: You cannot post the goods into the block stock if stock in in-transit is valuated, No Finance document will be created, supporting documents can be attached in the Stock transfer order, Goods receipt, goods issue, Notifications can be activated, Goods movement document can be printed, One step procedure not supported and delivery charges can be added using purchasing schema by condition type, material valuation will be based on the issuing plant. When your warehouse is busy with stock being moved in and out several times a day, it is possible to lose track and issue a transfer order with the incorrect details. Get a demo. You can apply filters to transfer orders to refine your results. While the One-Step Method is relatively simple, the Two-Step Method is better from a functional point of view and financial auditing. Showing results for. Only the quantity at the respective locations change. In the one-step process, the stock transfer issue and receipt are created in the same step, enabling users to issue the goods to their intended destination through a single stock transport order. User Count. While this process follows the same steps as the stock transfer without delivery, there are a few additions to consider when adding delivery:.

I think, that you are not right. I am assured. I can prove it. Write to me in PM, we will talk.