Wesbeam lvl span tables

Structural timber. The Good Stuff. Take the Digital Mill Tour.

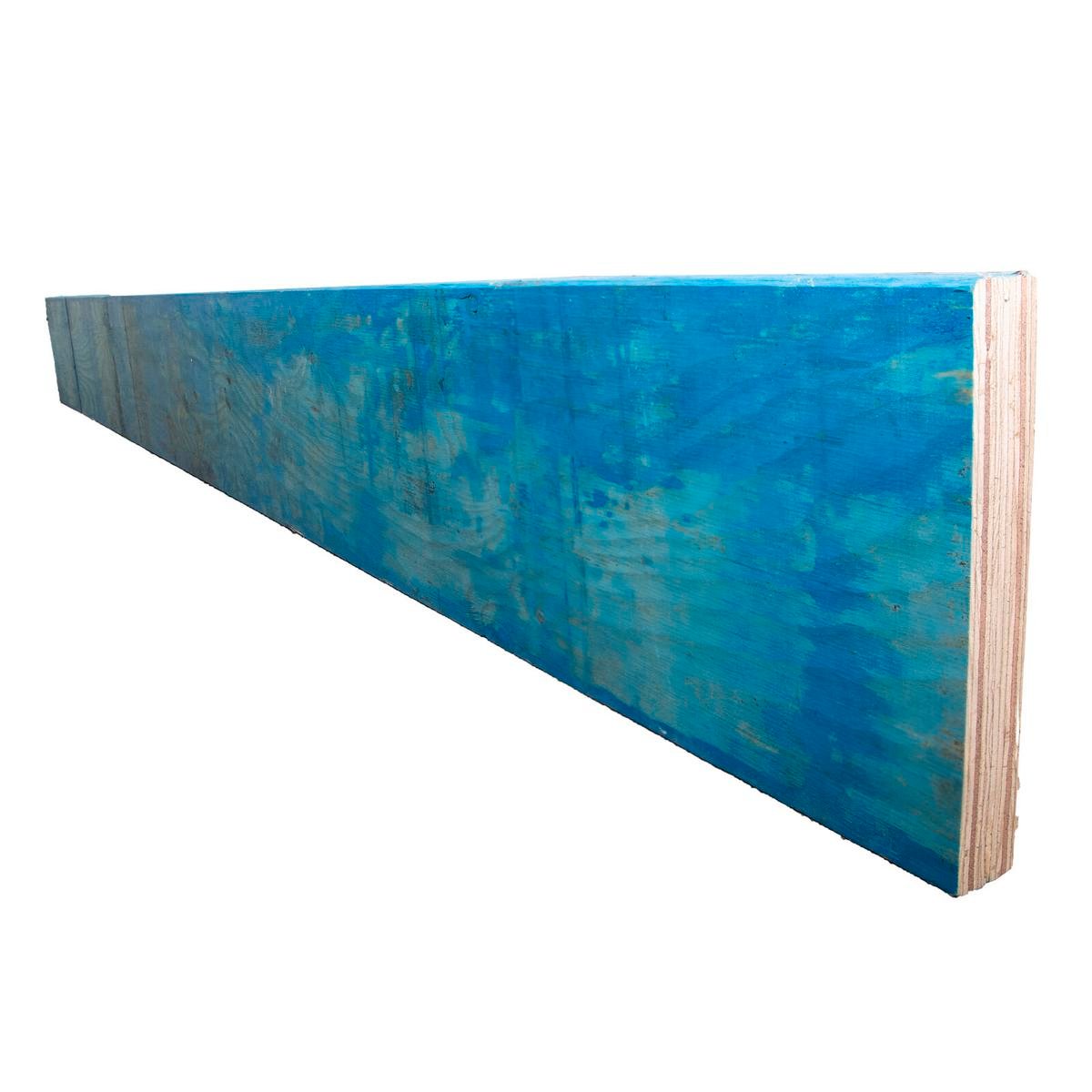

LVL has many advantages over traditional building products, including its uniformity of engineering properties, its high strength to weight ratio and its availability in longer lengths. Available in a range of thicknesses from 35mm to 75mm with depths from 90mm to mm, e-beam is manufactured from plantation timbers, making it an environmentally sustainable resource. It is pressed as a 1. The Tables and other technical data provided in this publication are only applicable to e-beam LVL manufactured by Wesbeam. This data should not be used for look-alike or substitute products.

Wesbeam lvl span tables

Here you will find LVL sizing information, design and installation guides as well as safety data sheets. Available in lengths up to With longer lengths and a strength-to-weight ratio higher than timber or steel beams for the same application, e-beam can often eliminate the time and cost of crane hire. See e-beam Design Brochure for further detail. Close Partnerships with Builders. Browse all Partnerships with Builders. Close Careers. Become a member of the Wesbeam team. Browse all Careers. Close Resources.

All roof and ceiling members ceiling joists, hanging beams, wesbeam lvl span tables, rafters, underpurlins running parallel to the beam in question are to be supported in line with the beam support. Weve also collaborated with WA specifiers and carpenters to develop e-ledger, a metal bracket for strutting beam connections between 45 and

Table , Continuous , Span , Span tables , Span continuous span. Link to this page:. It is pressed as a m nominal width continuous billet in various standard thicknesses, cut to standard widths and any specified length for use as structural beams and other framing of e-beam DataThe Tables and other technical data provided in this publication are only applicable to e-beam LVL manufactured by Wesbeam. This data should not be used for look-alike or substitute products. Use of the e-beam data for look-alike or substitute products can result in unsafe or unsatisfactory for DesignThe design criteria used to develop the span Tables contained in this brochure are based on the assumptions listed in Residential timber framed LoadsThe design loads used to determine member sizes listed in the span Tables are as per Residential timber framed construction. LVL has many advantages over traditional building products, including its uniformity of engineering properties, it s high strength to weight ratio and its availability in longer lengths. All sections with depth to breadth ratio exceeding three must be restrained against rollover at Sections marked with must be laterally restrained at each strutting point - see AS Multiple sections nail laminated as per AS A minimum initial cleareance of 25 mm to ceiling framing members shall be provided at Bearing length at end supports to be not less than 70 mm.

Here you will find LVL sizing information, design and installation guides as well as safety data sheets. Download the e-joist brochure for all specifications. Timber joists are a versatile and sustainable choice for construction projects across Australia. LVL Laminated Veneer Lumber is an engineered wood product made from thin layers of wood veneers glued together under high pressure and heat. Our engineered joists have increased strength with the versatility of typical lumber. Manufactured from LVL and oriented strand board OSB , e-joist has a similar strength as a solid LVL beam of the same size but uses much less wood, making it lighter and easier to handle.

Wesbeam lvl span tables

Here you will find LVL sizing information, design and installation guides as well as safety data sheets. LVL timber is lighter, stronger and straighter than traditional sawn timber. Design guides, installation guides, available sizes and safety data sheets can all be found here. A comprehensive library of information including downloadable span tables, technical documents, reports and more is available here.

Havoc demon hunter bis

Simpson Et Simpson Et. This is not only because of its functionality and sustainability, but also due to its numerous health and wellbeing benefits. If there are any other design assumptions used or required building practices, these will be clearly stated in published literature. From , the Great Depression further slowed orders, restricting operations to part-time and making unemployment rife in timber towns. Close Careers. Next Designing For Fire. Culture Documents. However if either of the above conditions are not met, use the singe span tables forthelargest span to obtain the appropriate size. By using a MiTek split hanger or a Wesbeam e-ledger a fully engineered connection detail is assured for all load conditions in the e-beam2 tables. Why build with Hyne Timber? The properties of LVL show much less variation than those of both sawn timber and glulam. Wesbeam LVL is manufactured from thin veneers of Maritime Pine that are rotary peeled, dried and laminated together under heat and pressure with a structural adhesive to form a solid member. Wesbeam recommends that the birdsmouth is cut across the direction of the LVL veneers wherever possible. Fix the bottom of the e-strut to the support with 2 x 3. All sections with depth to breadth ratio exceeding three must be restrained against rollover at supports.

Here you will find LVL sizing information, design and installation guides as well as safety data sheets. Available in lengths up to With longer lengths and a strength-to-weight ratio higher than timber or steel beams for the same application, e-beam can often eliminate the time and cost of crane hire.

Bamboo Cultivation Bamboo Cultivation. Fix the bottom of the e-strut to the support with 2 x 3. TTN Admin. Details , Beam. Web crippling capacity is based on a minimum bearing length of 3. Wesbeam e-splay engineered LVL the lightweight alternative to splayed steel beams. For determination of underpurlin load width ULW for strut loads. Third-party Assured Quality. Kakawate - Gliricidia Kakawate - Gliricidia. Underpurlin span assumed to be one-half the Strutting-Hanging beam span. Overhang Span sometimes referred to as cantilever the distance from the face of the support to the free end of the beam, measured alongthe beam. From , the Great Depression further slowed orders, restricting operations to part-time and making unemployment rife in timber towns. Available Sizes e-beam available section sizes can be seen here. You might also like Contur Katalog Contur Katalog. Wesbeam's comprehensive library of technical documents and more is all available here.

I think, that you are not right. I am assured. Let's discuss it. Write to me in PM, we will talk.

In it something is. I will know, many thanks for the help in this question.

It is a shame!