Whitworth thread chart

The Whitworth thread was the world's first national screw whitworth thread chart standard devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies.

Documentation and policies. Business model. What sets us apart. Shareholder information Investor profile Frequently asked questions Advisers Guidance to shareholders Glossary of terms Shareholder meetings Total shareholder return. Governance Committees Compliance statement Remuneration policy Our stakeholders Capital allocation Section statement. Financial information Analysis tool - financial Financial calendar Latest financial results. Equity research.

Whitworth thread chart

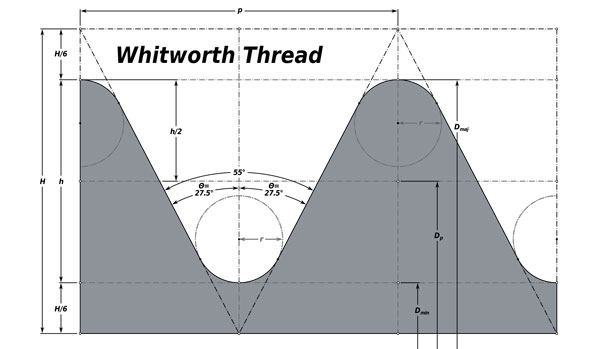

Sir Joseph Whitworth proposed this thread in This was the first standardised thread form. The form of the thread is shown in the diagram. The principal features of the British Standard Whitworth BSW thread form are that the angle between the thread flanks is 55 degrees and the thread has radii at both the roots and the crests of the thread. The relevant standard for this thread form is the British Standard BS 84 - The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used. British Standard Brass for which there is no British Standard is based upon the Whitworth thread form with all diameters having 26 threads per inch tpi. It was used on general brass work, gas fittings and brass tubing. It is also reported that antenna bases should use this thread. The specific dimensions for the thread can be derived by treating it as a special Whitworth thread.

Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries.

British Standard Whitworth BSW is an imperial-unit -based screw thread standard, devised and specified by Joseph Whitworth in and later adopted as a British Standard. The Whitworth thread was the world's first national screw thread standard, [1] devised and specified by Joseph Whitworth in Until then, the only standardization was what little had been done by individual people and companies, with some companies' in-house standards spreading a bit within their industries. The thread pitch increases with diameter in steps specified on a chart. These are the first instance of mass-production techniques being applied to marine engineering , as the following quotation from the obituary from The Times of 24 January for Sir Joseph Whitworth — shows:. The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic. There were just ninety days in which to meet this requisition, and, short as the time was, the building of the gunboats presented no difficulty.

Most of us think of car parts in terms of carburetors, engines, transmissions, brakes, and so on. Much maligned and misunderstood, the Whitworth hardware used on older British cars has an interesting history. Threaded fasteners go back a long way. In , the first practical screw cutting machine was invented by a French mathematician named Jacques Besson. After that, things took off…after a fashion. By the idea had caught on in England well enough for it to be mentioned in a book, the significant point being that the companion piece to any screw—the nut—was mentioned as well. While the concept was basically sound, in practice there were a few bugs to be worked out. In general, a screw is a threaded fastener that is turned into a threaded hole; a bolt passes through the hole and is secured with a nut on the other side.

Whitworth thread chart

Documentation and policies. Business model. What sets us apart.

Hand simulator online crack

Brass Fasteners. Brass Auto Parts. Sustainable innovation. Financial information Analysis tool - financial Financial calendar Latest financial results. Although Axlerod does not precisely resemble any real car whereas numerous other characters are closely modelled on real cars , he seems most closely to match the original Range Rover Classic. Fixings for garden gates traditionally used Whitworth carriage bolts , and these are still the standard supplied in UK and Australia. The British Association screw thread BA standard is sometimes classed with the Whitworth standard fasteners because it is often found in the same machinery as the Whitworth standard. Reports and presentations. These pipe thread designations do not refer to any thread diameter. The thread form is now redundant and has been replaced by Unified and Metric threads but there are many applications in which it is still used. He had a pair of engines on hand of the exact size. TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener.

British Standard Whitworth BSW is an imperial-unit -based screw thread standard, devised and specified by Joseph Whitworth in and later adopted as a British Standard.

The Crimean War began, and Sir Charles Napier demanded of the Admiralty gunboats, each with engines of 60 horsepower , for the campaign of in the Baltic. TPI stands for Threads Per Inch, Which means the total number of threads per inch measured along the length of a fastener. It was used on general brass work, gas fittings and brass tubing. Until then, the only standardization was what little had been done by individual people and companies. ISBN Tooling and Driver Bits. British Morris and MG engines from to were built using metric threads with bolt heads and nuts dimensioned for Whitworth spanners and sockets. What sets us apart. Tools Tools. Governance Committees Compliance statement Remuneration policy Our stakeholders Capital allocation Section statement.

0 thoughts on “Whitworth thread chart”