Diy circular saw track

Educational woodworking content, early access to new products, and flash sale discounts for subscribers only.

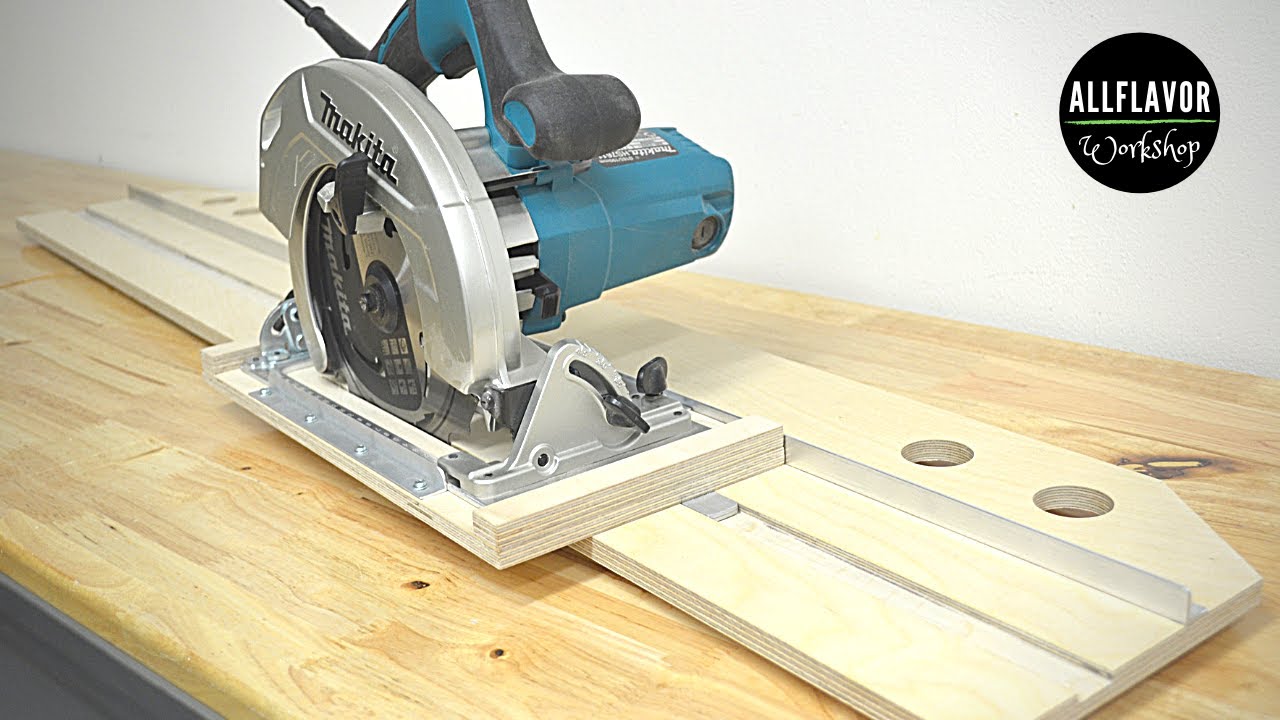

In this Instructable, I will be making a track saw guide. This guide is very stable, and extremely accurate. You too can have the same experience, if done right. Hopefully my instructions are clear and easy-to-follow. Enjoy :. Check out the video for a more in-depth take. Instagram www.

Diy circular saw track

Breaking down plywood is an issue for most hobbyist woodworkers. There are retro-fit products available that turn your circular saw into a track saw. Lower the saw until it touches the saw and then raise it up just a bit to give plenty of clearance. Now, place some stock under the fence and confirm the blade will cut all the way through. You could purchase your plywood at the home center and then have them cut it down on their panel saw. The other option, and what I do in the video above, is to utilize the factory edge on the plywood. Examine each edge and pick the one that is the straightest. This is to give enough room to make a nice zero clearance cut as the last step. With the saw in place flip the fence over with the factory edge facing right and, up against the saw and then strike a line on each side to mark its basic location. Use your saw to cutout the jig, free-hand, at those marks. Glue the fence down and either drive screws , brad nails, or use clamps to keep it tight against the jig until the glue dries. Run your saw along the fence and make a zero clearance cut keeping even and consistent pressure against the fence. Measure and mark the piece to be cut and set the jig right at the marks. Clamp the jig down and run the saw along the saw guide again keeping even and consistent pressure against the fence. It allows you to make crosscuts and shorter rip cuts.

Hopefully, this DIY track saw inspires you to find solutions to your tool limitations — and helps you get cuts as square as the Minecraft universe, diy circular saw track. Our Blog Our curated woodworking blog dedicated to giving you useful tips and tricks merope gaunt can incorporate on your next project The KMWDF Learn more about the KMWDF's mission and how you can help woodworkers in need Creator of the Week Want your work to be featured in our weekly woodworking newsletter? I recommend using a spiral upcut bit for cutting slots.

.

We use cookies to provide basic functionality and improved security. We also use 3rd-party cookies to improve your browsing experience and for targeted advertising. View our Privacy Policy. A circular saw is one of the very basic tools every workshop should have. It is one of the most common beginner power saws and a great tool to use when you are starting in the craft. Due to its versatility, in many cases it can replace a table saw if used correctly.

Diy circular saw track

If you want to cut large sheets of plywood, it is an almost impossible job to do this with your table saw. Unless you have an industrial table saw, of course. A good solution to make these cuts is a track saw. It is much smaller, and you can cut perfectly large sheets of plywood with it. The only downside is that track saws are expensive. To use this circular saw guide, you can simply use the circular saw that you already have in your workshop. Al you need is to make an adjusted circular saw track. Thanks to the step-by-step instructions and the free DIY circular saw guide plans you can download in this blog, you can easily build a DIY circular saw guide rail yourself. From now on, there will be no more struggling with oversized sheets of plywood on the table saw and no more dangerous situations. On top of that, making this DIY circular saw track is a fun and dirt cheap project to make.

Movavi video editor 14 plus crack

Now measure from the router bit to the end of the router base. Everybody hates sanding, but a professional looking project depends on it. Then use a router to cut a slot between the other two points you can also just do two slots — up to you. Make sure to keep the saw against the fence for the entire cut. You too can have the same experience, if done right. The only edge that needs to be straight is the side of the top fence your circular saw rides against. Subscribe to the KM Tools Newsletter Sign up and receive free build plans for the Katz-Moses Router Table as well as exclusive access to: Early notifications for upcoming product launches Sales and discounts on our most popular products Weekly educational woodworking content Your e-mail. Free Shipping On U. There are a thousand floating shelf examples, videos, and plans out there. Why Build this Sled? Flip the sled upside down, then put a t-bolt through the hole in the bottom fence and the hole you just drilled. This should help with lining up the track onto the work surface. Sign up and receive free build plans for the Katz-Moses Router Table as well as exclusive access to:. Got any ideas for improving or modifying this circular saw sled? Take a straight object to make a straight line.

Make your own quick cheap circular saw guide. In this video I'll show you how to quickly make your own quick cheap circular saw guide rail to make easy straight cuts like your own little cheap track saw!

Got any ideas for improving or modifying this circular saw sled? Clamp the jig down and run the saw along the saw guide again keeping even and consistent pressure against the fence. Find a location on your saw for the placement of the second track. Also, add some wax to help with the friction. You need to leave some extra meat for cutting the zero-clearance edge later on. Now measure from the router bit to the end of the router base. Track saws are no doubt useful. Time to slather this sucker down with your favorite finish. It can even help you put off buying a table saw for a while to an extent. This only made it look cool.

The charming answer