Iso 2768-m

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, iso 2768-m, it is almost impossible iso 2768-m get precisely the exact dimensions for a batch process.

CNC Machining Service. Injection Molding. Urethane Casting. Sheet Metal. Compression Molding. Die Casting.

Iso 2768-m

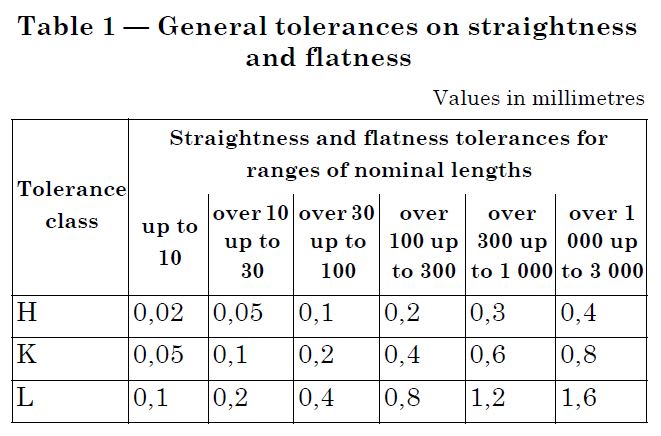

One internationally recognized standard that addresses tolerances in technical drawings is ISO ISO provides guidelines for general tolerances, ensuring compatibility and functionality across various industries and applications. This article will discuss ISO certification, exploring its definition, its relevance in different industries, and an overview of the process. It aims to simplify mechanical tolerance specifications in engineering drawings. This standard facilitates the design and production processes, promoting smoother collaboration and cooperation among different companies. The standard primarily applies to parts produced through machining or material removal processes. When tolerance ranges are not explicitly specified for a particular dimension, ISO should be followed. The ISO standards are relevant to a wide range of industries. ISO is relevant to a wide range of manufacturing industries and products, including the: automotive, aerospace, electronics, and electrical industries. These sections establish standards for mechanical precision, with the goal of simplifying technical drawings. ISO is entitled "General tolerances for linear and angular dimensions," which defines precision levels categorized as fine f , medium m , coarse c , and very coarse v. ISO focuses on "Geometrical tolerances for features," and uses different precision levels or tolerance classes: H, K, and L. ISO mK is commonly utilized in the manufacturing of sheet metal components, while manufacturers of machined components may opt for ISO fH. Both ISO part 1 and part 2 are discussed in further detail in the sections below:.

Contact us now, iso 2768-m. There are four tables here with respect to general geometric tolerances of dimensions iso 2768-m further information. It outlines the quality management system requirements for organizations involved in the design, development, production, installation, and servicing of automotive-related products.

Every feature on products or parts has a size and a geometrical shape. To ensure that the size and geometry of all features are made as required, we should carefully take care of the tolerancing on the drawing. Nothing shall be implied or left to interpretation in the workshop or inspection department. General tolerances for size and geometry make it easier to ensure that the size and geometry of all features can be done as requested. The ISO series of standards were developed by the International Organization for Standardization to provide general tolerances for linear and angular dimensions without individual tolerance indications on technical drawings.

Ensuring this precision across diverse products and components often demands the adoption of universally recognized standards. ISO , with its meticulous guidelines, represents one of these crucial standards. The term ISO might appear to be just another technical jargon, but for those in the realm of manufacturing, it carries a weight of significance. ISO refers to the International Standard for general tolerances. The primary objective of this standard is to simplify drawing indications and thus, expedite the design and manufacturing process.

Iso 2768-m

Manufacturing metal and plastic parts occur in large numbers every day. However, fabricating these parts without deviating from original designs can be very complicated. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process. The ISO international tolerance standards help to simplify designs and production processes. Machinists and designers can decide the level of deviation from the original specifications, giving a controlled margin for error. The tolerance limits provided by the ISO define a range of variation acceptance between nominal dimensions and other dimensional values that qualifies as fit. In this article, we will discuss the details of ISO to help you better understand this tolerance standard. Stay with us. Creating this international standard and its implementation make designing and manufacturing more accessible and convenient. Partnerships between manufacturing companies are also more seamless.

Ring doorbell mount

Table 1: Tolerances on Linear Dimensions. Industry Reports. Contact us now. Its general tolerance standards are summarized below. Permissible deviations in mm. Scroll to Top. Contact Us. Necessary Necessary. It provides a set of tolerances that can be applied to various dimensions to ensure the interchangeability of parts and the accuracy of measurements. Figure 4: Geometrical tolerance example. Sometimes, it is almost impossible to get precisely the exact dimensions for a batch process.

Specialize in CNC machining, 3D printing, urethane casting, rapid tooling, injection molding, metal casting, sheet metal and extrusion.

They are dimensions of components produced using metal removal. Similar to Flatness, we define two planes separated by a gap equal to the permissible deviation in Table 5. Can you still use them? Business Leadership. For example, instead of defining an upper limit and a lower limit, in Figure 4 we define a region between two references i. Tolerance Class Designation Description Permissible dimensional deviation in mm —. Since the nominal feature lengths only start at 0. The cookie is used to store the user consent for the cookies in the category "Other. Visit our website to learn more or to request a free, no-obligation quote. Sam March 7, am. It provides a set of tolerances that can be applied to various dimensions to ensure the interchangeability of parts and the accuracy of measurements.

0 thoughts on “Iso 2768-m”