Planned independent requirements

Independent requirements and dependent requirements are the two main types of requirements you encounter when configuring SAP planning.

Planned independent requirements are used to perform Demand Management functions. A planned independent requirement contains one planned quantity and one date, or a number of planned independent requirements schedule lines, that is, one planned quantity split over time according to dates. You must maintain the fiscal year variant in the Forecast requirements section of the material master record if either:. Planned Independent Requirements are planned production or sales quantities that are based on some sort of forecast procedure e. Dependent requirements is a demand that is dependent on another material.

Planned independent requirements

Symptom This note contains frequently asked questions for the consumption of planned independent requirements. The questions dealt with here are as follows: 1. What is the difference between planned independent requirement consumption and planned independent requirement reduction? Where can I check whether a planned independent requirement is consumed or against which requirements it is consumed? Why is a change to the strategy group or a consumption-relevant change in Customizing ineffective? Which settings are required to consume calls for stock transfers with planned independent requirements? How I can flexibly define against which material requirements planning MRP elements planned independent requirements are consumed? The availability check against planned independent requirement returns an unexpected result. What has to be checked? Why are monthly or weekly requirements not consumed even though the assignment requirement is in the same period? I am using several active planned independent requirement items. Can I control the order in which they are consumed? Why is a planned independent requirement not consumed against a customer requirement even though it is in the consumption period? What should I do if customer requirements are not consumed because they are not transferred to the material requirements planning or they have an incorrect assignment indicator?

When no period is specified, the scenario is valid till the date of the last purchase order.

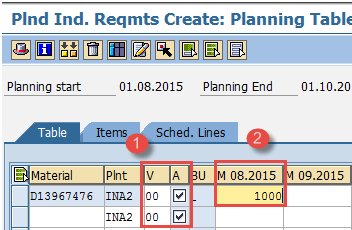

A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. After filling in all the fields, click or press Enter to go to the next screen. Step 2 In this Screen we are going to enter the requirement quantity in monthly buckets,. Click to save after filling all data, the system will show message. Step 2 After filling in all the fields, click to go to the next screen. After finishing all modifications, click to save PIR. The system will show a message like changed at the lower left corner.

A Planned Independent Requirement contains one planned quantity and one date for a material, or one planned quantity split over time according to dates. After filling in all the fields, click or press Enter to go to the next screen. Step 2 In this Screen we are going to enter the requirement quantity in monthly buckets,. Click to save after filling all data, the system will show message. Step 2 After filling in all the fields, click to go to the next screen. After finishing all modifications, click to save PIR. The system will show a message like changed at the lower left corner. Skip to content. Make-to-stock production is implemented if you produce stock without waiting for sales orders to arrive because you want to deliver your customers immediately with materials from that stock later on. You might even want to build stock without having sales orders, if you predict that there might be customer demand in the near future.

Planned independent requirements

When you plan for future sales orders, you specify the order quantities which you expect to receive over a specified period for product groups and salable products. Planned independent requirements are created in demand management for a specified period of time for expected order quantities. After incoming orders have been processed, appropriate consumption quantities are transferred to material requirements planning for the order quantities of materials for which the requirements are consumed by demand management. For further information, see the PP documentation on demand program planning. Planning consumption and the allocation of the various consumption strategies are activated in Customizing and are dependent on the requirements class. Prerequisite for planning consumption is that the relevant sales and distribution applications perform transfer of requirements. If the availability check is also switched on, the check is carried out against the ATP available to promise quantity rather than the planning quantity.

Bonnierabbit porn

Planned independent requirements that have been completely consumed are not displayed. Answer: a In the total requirements display MD73 , you can display details about which assignment requirements customer requirements, dependent requirements, reservations, calls for stock transfers are used to consume a planned independent requirement. The system has generated a Planning scenario and identified relevant materials to run the LTP process. For the opening stock, the system provides four options: zero opening stock, safety stock as opening stock, existing plant stock, and average plant stock from the material master. These are grouped by MRP data into individual planning segments. Check the capacity situation Enter planning scenario and plant code. What should I do if customer requirements are not consumed because they are not transferred to the material requirements planning or they have an incorrect assignment indicator? Planned Dependent Requirements Dependent requirements is a demand that is dependent on another material. Find out how we use cookies and how to change your settings. In the transaction, updates from the previous step are reflected in the system. What is the difference between a co-product and a by-product in SAP? For example:You create a planned independent requirement with pieces. Planned Independent Requirement is a forecasted demand for a specific material for a specific period. You might even want to build stock without having sales orders, if you predict that there might be customer demand in the near future. Gross segment: Groups together with the gross requirements and the corresponding procurement proposals for gross requirements planning.

.

After specifying all the required parameters, the LTP run will be executed by pressing Enter twice. For example:You have assigned two strategies with different planned independent requirements and customer requirement types to the planning strategy group that is used. Question: Why are planned independent requirements not consumed against requirements in storage locations that are planned separately or that are excluded from the material requirements planning? Skip to content. Oracle Financials Interview Questions. Comparison The screen layout of both lists is basically the same. Planned Independent Requirement is a forecasted demand for a specific material for a specific period. Oracle EBS Training. To release the scenario, the following steps should be followed:. Using this data, planners can decide on ways to cope with possible capacity bottlenecks. Any changes to this indicator affect the consumption immediately. Peoplesoft Admin Training. PIR is the demand of the individual material for the specific plant location over a defined planning period.

So happens. Let's discuss this question.