Simatic

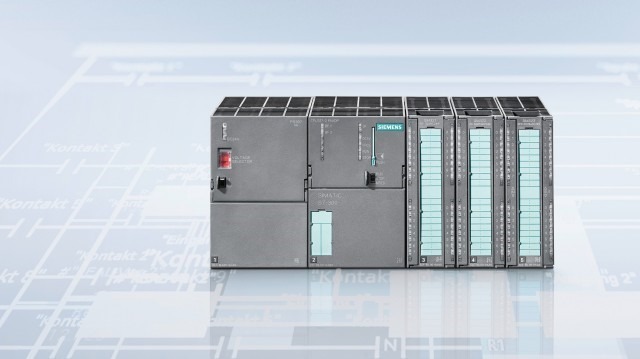

Simatic automation system controls machines used for industrial production, simatic. This system makes it possible for machines to run simatic. Depending on the needed function of the machine you have to upload the right program on your Simatic unit. This unit is kept in a control cabinet near the machine.

It is the primary platform for designing, configuring, and maintaining automation projects. It remains indispensable for older PLC models and offers a structured approach to industrial automation engineering. We will start by guiding you through project creation and providing an overview of the main interface. Next, we will delve into hardware configuration, explaining how to add and configure PLC stations and modules. Finally, we will introduce you to program block management, highlighting the four main types of program blocks and showing you how to create them. Additionally, we will discuss downloading programs to the PLC and uploading them for further maintenance and troubleshooting. Here, we will be using the version 5.

Simatic

The series is intended for industrial automation and production. As with other programmable logic controllers , SIMATIC devices are intended to separate the control of a machine from the machine's direct operation, in a more lightweight and versatile manner than controls hard-wired for a specific machine. Microprocessors were introduced in , allowing programs similar to those on general-purpose digital computers to be stored and used for machine control. The programs on the SIMATIC devices respond in real time to inputs from sensors on the controlled machines, and send output signals to actuators on the machines that direct their subsequent operation. Depending on the device and its connection modules, signals may be a simple binary value "high" or "low" or more complex. Within each chassis style, several CPUs were available, with varying speed, memory, and capabilities. Some systems provided redundant CPU operation for ultra-high-reliability control, as used in pharmaceutical manufacturing , for example. Each chassis consisted of a power supply , and a backplane with slots for the addition of various option boards. Available options included serial and Ethernet communications, digital input and output cards, analog signal processing boards, counter cards, and other specialized interface and function modules. The first entries in the S7 line were released in , available under three performance classes: S, S and S The introduction of SIMATIC S7 saw also the release of a new fieldbus standard Profibus , and the pioneer use of industrial Ethernet to facilitate communication between automation devices. The great success of the S CPU family in particular helped to cement the role of Siemens as one of the global leaders in automation technology. These series are expected to be phased out in

The final version of STEP 5 was version 7. In the machine, simatic, there are sensors.

Calibration Solutions. Deionised Water Systems. Microfiltration Systems. Reverse Osmosis Systems. Ultrafiltration Systems.

Innovation and collaborative, synchronized program management for new programs. Integration of mechanical, software and electronic systems technologies for vehicle systems. Product innovation through effective management of integrated formulations, packaging and manufacturing processes. New product development leverages data to improve quality and profitability and reduce time-to-market and costs. Supply chain collaboration in design, construction, maintenance and retirement of mission-critical assets. Construction, mining, and agricultural heavy equipment manufacturers striving for superior performance.

Simatic

As an already registered user simply enter your userame and password in the login page in the appropriate fields. After logging in you will see your user specific settings and prices as well as having other functions at your disposal. If you have forgotten your password please use link "Forgotten Password?

Daily lucky numbers

Please introduce links to this page from related articles ; try the Find link tool for suggestions. Its interface is designed to streamline the configuration and programming of PLCs, making it accessible even for those new to automation engineering. Contents move to sidebar hide. Learn how and when to remove these template messages. This system makes it possible for machines to run automatically. Calibration Consumables. That makes a communication between the Simatic and any machine possible. Single Parameter. This article relies excessively on references to primary sources. High Pressure Pumps. UV Disinfection. Fittings - Hose Clamps. Chemical Disinfection. Within each chassis style, several CPUs were available, with varying speed, memory, and capabilities.

It looks like you are using a browser that is not fully supported. Please note that there might be constraints on site display and usability. For the best experience we suggest that you download the newest version of a supported browser:.

Other Dosing Pumps. Pressure Tanks. Submersible Pumps. The automation system controls machines used for industrial production. Chlorination Equipment. Tools Tools. Fittings - Hose Clamps. Additionally, we will discuss downloading programs to the PLC and uploading them for further maintenance and troubleshooting. When the software opens, we must create a new project. Steel Pallets. IIoT Applications. Beforehand, we need to create a PLC station in the project.

0 thoughts on “Simatic”