Ur10 manual

This manual is periodically reviewed and revised.

The ur10 is the biggest in the universal robot cobot series with a load that is up to 10kg. The ur10 manual is the perfect choice for processes like pick and place, palletizing, assembly, packaging etc. With this manual it is very easy to set up with clients reporting on average of half a day. An operator who is not familiar with robot can mount it, unpack the robot and package its first job in less than an hour. The original technology with 3D visualization and intuitive helps the new operators of ur10 to feel incredibly comfortable programming the ur10 robot. What they need to do is to move the robot arm desired positions and simply press the arrow buttons on the screen touch table. Furthermore, it has the advantage of offering one of the quickest profit times in the industry and provide extraordinary security.

Ur10 manual

.

Adjustment of program waypoints will likely be required.

.

Table Of Contents. Table of Contents. Quick Links. Universal Robots. Previous Page.

Ur10 manual

The UR10e is our medium duty industrial collaborative robot that combines both long reach and high payload. This cobot will seamlessly integrate into a wide range of applications and delivers endless automation possibilities. Automating repetitive tasks has, from a technology standpoint, never been the challenge. The challenge has been finding the right tool that will enable you to adapt to the future of manufacturing. Our most popular collaborative, industrial robot, the UR10e, is supporting customers globally in automating regular tasks such as palletizing, machine tending and welding. It also enables the development of unbelievably creative solutions, such as plastic picking in rivers, glass manufacturing, or car fueling solutions.

Personal care assistant salary

Personal Growth Documents. If controller is equipped with long-hole brackets, make sure to replace them with circular-hole brackets. Stand back and monitor the robot performing its first program cycle as C position disagreement expected. Large metal objects can be discharge paths without being grounded. Error on 48V powerbus to robot arm Check 48V output from Power supply. Remove blue lid on Wrist 1 joint. There are so many companies you can contact today for your ur10 manual in UK, US and other countries of the world that can integrate universal robots including ur Gently put back the gasket. C68 communication error b Do a Complete rebooting sequence as per section 5. It must be connected to the right connector on the mother board 7. Connect power and verify that teach pendant works properly.

Table Of Contents. Table of Contents.

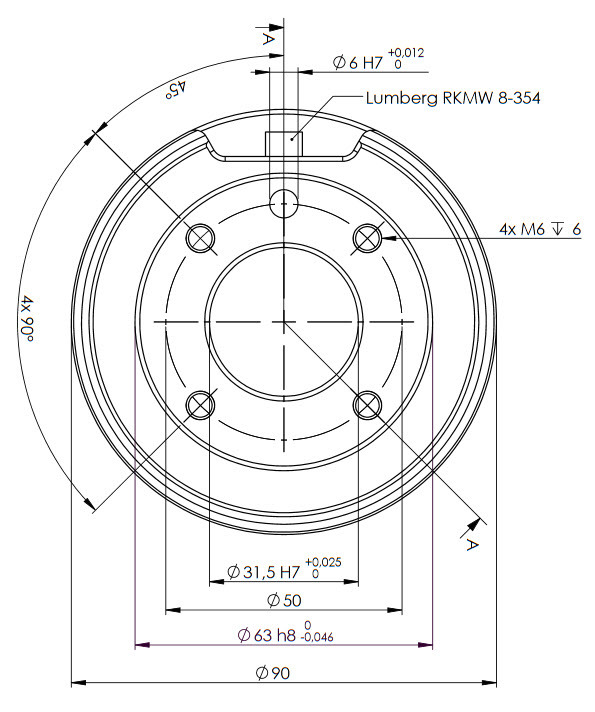

Check for short circuit. Before performing service related operations, always make sure to stop the robot program and disconnect the main power to any potential dangerous tool on the robot or in the work cell. Remove blue lid on Wrist 1 joint. Replace tool flange and reconnect connectors as illustrated. Gently put back the gasket. Ineo Ineo When updating, it must be done in steps i. Software version before 3. Remove the 2 nuts M6 in the bottom of controller module. Insert all connectors and plugs back into their correct positions. If they are correctly inserted, use a tool to press on the pins to ensure they are pushed all the way in. C75 Joint encoder error Magnetic encoder error Absolut encoder Invalid decode: Readhead a Do a Complete rebooting sequence as per section 5.

In it something is also to me it seems it is excellent idea. I agree with you.